Introduction

Did you know that stainless steel seamless pipes are often the go-to choice for industries facing extreme pressure and harsh environments? Their ability to withstand corrosion, high temperatures, and immense pressure makes them a critical component in various industries.

In this article, we will dive into the essential aspects of stainless steel seamless pipes. You will learn about their unique manufacturing process, key advantages, and various applications. Understanding these factors will help you make more informed decisions in choosing the right pipes for your industry.

Understanding Stainless Steel Seamless Pipes

What Makes Stainless Steel Seamless Pipes Unique?

Stainless steel seamless pipes are made by extruding a solid billet through a mold to form a hollow tube, without the need for welding. This manufacturing process gives seamless pipes a uniform structure, free of any weak points, cracks, or joints. The absence of welding seams allows these pipes to withstand greater pressure and temperatures, making them more durable and reliable than their welded counterparts.

In contrast, welded pipes are made by rolling a metal sheet and welding the edges together, which introduces potential weak spots at the seams. As a result, welded pipes are less suitable for high-stress and high-temperature applications, as they might fail under such conditions. Seamless pipes, with their stronger, more consistent structure, are the preferred choice in critical applications such as oil and gas pipelines, chemical processing, and power generation systems.

Key Advantages of Stainless Steel Seamless Pipes

Strength and Durability: Seamless pipes can withstand higher pressures than welded pipes, making them suitable for use in high-stress environments. Their lack of weld seams ensures that they do not suffer from the potential weaknesses found in welded pipes.

Corrosion Resistance: Stainless steel’s chromium content provides excellent resistance to rust and corrosion, even in harsh environments exposed to moisture, chemicals, and extreme temperatures. This is particularly important in industries like chemical processing, where pipes are exposed to corrosive substances.

High-Temperature Resistance: Stainless steel seamless pipes, especially those made from alloys like 316, can perform well at elevated temperatures without compromising their structural integrity. This feature makes them ideal for applications in heat exchangers, power plants, and other high-temperature environments.

Types of Stainless Steel Seamless Pipes and Their Applications

Stainless steel pipes come in various grades, each offering different benefits depending on the application:

| Stainless Steel Type | Key Features | Common Applications |

| 304 Stainless Steel | Versatile, good corrosion resistance | Food processing, pharmaceutical industries, chemical equipment |

| 316 Stainless Steel | Superior corrosion resistance, resistant to chlorides and acids | Marine environments, pharmaceutical applications, chemical industries |

| 321 Stainless Steel | Excellent heat resistance, stable at high temperatures | Aerospace applications, heat exchangers |

Each type of stainless steel has specific benefits, so it's important to choose the right type based on the requirements of your application.

The Manufacturing Process of Stainless Steel Seamless Pipes

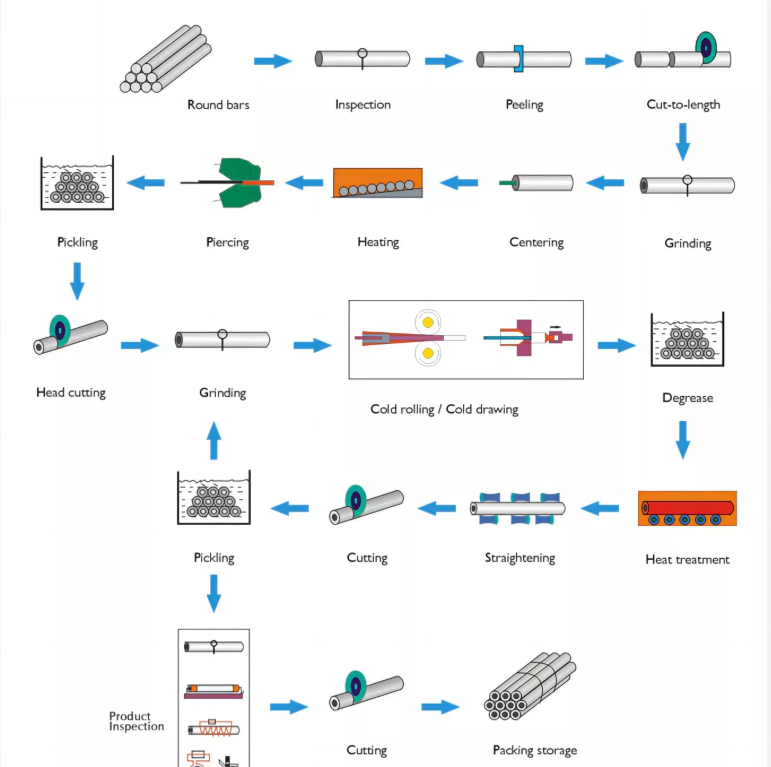

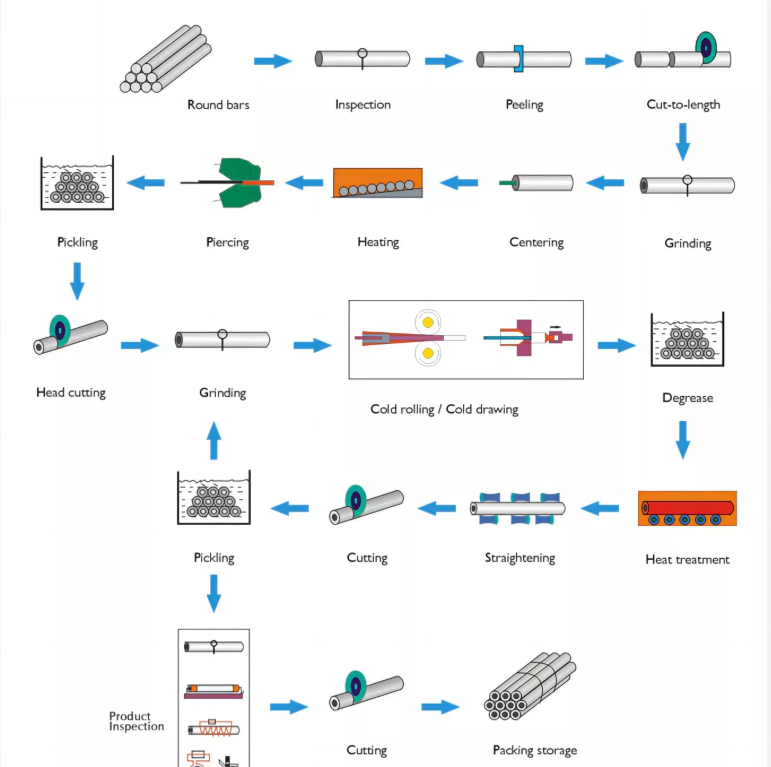

Step-by-Step Overview of the Manufacturing Process

The manufacturing process of stainless steel seamless pipes begins with the selection of high-quality stainless steel billets. These billets are carefully heated to high temperatures to prepare them for extrusion. The heated billet is then pierced to create a hollow tube, which is further elongated to the desired size through hot rolling and cold drawing processes.

After the pipe has been shaped, it undergoes heat treatment to improve its mechanical properties, such as strength and flexibility. The final step in the manufacturing process involves surface treatments like pickling and polishing to enhance the pipe’s resistance to corrosion and ensure a smooth finish.

Hot Extrusion and Cold Drawing Techniques

Hot Extrusion: In the hot extrusion process, the billet is heated to a high temperature, making it malleable, and then forced through a mold to form a hollow pipe. The process helps shape the pipe into its desired length and diameter. Hot extrusion is crucial for forming pipes that can withstand high temperatures and extreme conditions.

Cold Drawing: The cold drawing process is performed at room temperature, where the pipe is drawn through a die to reduce its diameter and wall thickness to precise measurements. This process also improves the mechanical properties and surface finish of the pipe, making it more durable and smoother for applications requiring precision.

Enhancing Quality: Surface Treatment and Testing

Surface treatments are essential in enhancing the durability and performance of stainless steel seamless pipes. Pickling, a process involving acid cleaning, removes any oxidation and scale from the surface. Polishing further improves the pipe’s surface finish, giving it a smooth, shiny appearance while enhancing its corrosion resistance.

Additionally, seamless pipes are subjected to various non-destructive testing (NDT) methods to ensure their integrity and performance. Methods such as ultrasonic testing and hydrostatic testing are commonly used to detect any internal flaws, while ensuring the pipes can withstand the pressures they are designed for.

Sizing and Wall Thickness Standards for Seamless Pipes

Stainless steel seamless pipes come in various sizes and wall thicknesses, each suited for specific applications. Wall thickness is a critical factor in determining how much pressure the pipe can handle, especially in high-pressure environments. Pipes are categorized according to industry standards, such as ASTM, EN, and JIS, which outline the necessary specifications for various applications.

Common pipe schedules include:

| Schedule | Wall Thickness (in inches) | Suitable Applications |

| Schedule 40 | 0.140 (for 1" pipe) | Medium-pressure applications |

| Schedule 80 | 0.179 (for 1" pipe) | High-pressure environments |

| Schedule 160 | 0.375 (for 1" pipe) | Very high-pressure environments |

Tip: When selecting a pipe, always ensure the wall thickness is appropriate for the pressure and temperature conditions of your application.

Performance and Key Applications of Stainless Steel Seamless Pipes

How Stainless Steel Seamless Pipes Resist Corrosion

The corrosion resistance of stainless steel pipes is primarily due to the chromium content in the alloy. When exposed to oxygen, the chromium forms a thin, protective layer of chromium oxide on the pipe’s surface. This layer prevents rust and degradation, even in aggressive environments. Special alloys, such as 316 stainless steel, offer enhanced resistance to corrosion, particularly in environments with high chloride concentrations, like marine or coastal applications.

Mechanical Properties: Strength and Durability

The mechanical properties of stainless steel seamless pipes, such as tensile strength, yield strength, and elongation, are crucial in determining their performance under stress. Stainless steel pipes are designed to withstand high levels of pressure and are commonly used in critical applications where pipe failure can result in significant damage or loss.

The strength of a pipe is determined by the grade of stainless steel used. Grades like 304 and 316 offer excellent strength and flexibility, ensuring reliability in demanding conditions.

Industry Applications of Stainless Steel Seamless Pipes

Stainless steel seamless pipes are widely used across various industries due to their strength, durability, and resistance to corrosion. Some of the key applications include:

Oil and Gas: Used in high-pressure pipelines, drilling equipment, and offshore rigs.

Chemical Processing: Transporting corrosive chemicals in reactors and pipelines.

Food and Pharmaceutical Industries: Ensuring hygienic conditions with corrosion-resistant, easy-to-clean pipes for food processing and medical applications.

Power Generation: Employed in heat exchangers, boilers, and cooling systems in nuclear and thermal power plants.

Choosing High-Quality Stainless Steel Seamless Pipes

Important Selection Standards and Certifications

When selecting stainless steel seamless pipes, it’s crucial to ensure they meet internationally recognized standards such as ASTM, EN, and JIS. These certifications ensure the pipes are manufactured to specific quality standards and are capable of handling the conditions they will face in service. For instance, ASTM A312 specifies the required mechanical properties for pipes used in high-pressure systems, ensuring they can withstand stresses without failure. Compliance with such standards guarantees that the pipes have undergone rigorous testing, ensuring they meet durability, safety, and performance requirements. Using pipes that are certified helps avoid failures, reduces the risks associated with substandard products, and ensures regulatory compliance in industries such as oil and gas, chemical processing, and power generation.

Inspection Methods for High-Quality Pipes

Several inspection methods are employed to verify the quality of stainless steel seamless pipes, ensuring they meet both the mechanical and safety standards:

Visual Inspection: This basic method involves closely examining the pipes for visible defects such as cracks, surface damage, or any imperfections that could compromise their integrity. It is the first line of defense in ensuring product quality.

Non-Destructive Testing (NDT): NDT methods like ultrasonic testing, eddy current testing, and magnetic particle testing are used to detect internal or near-surface defects without damaging the pipes. These techniques help identify cracks, voids, or other flaws that might affect the pipe’s strength and reliability in demanding applications.

Hydrostatic Testing: In hydrostatic testing, the pipe is subjected to internal water pressure to ensure it can withstand the operational conditions without leaking or bursting. This test simulates real-world pressure conditions and verifies the pipe’s strength and reliability in high-pressure systems.

How to Choose Pipes Based on Application Needs

Selecting the right stainless steel seamless pipe is essential for ensuring optimal performance and longevity in your system. There are several factors to consider when making the right choice:

Material: Different grades of stainless steel offer various advantages depending on the application. For example, 304 stainless steel is commonly used in general applications due to its excellent corrosion resistance. However, 316 stainless steel is preferred in highly corrosive environments, such as marine applications or chemical processing, because of its enhanced resistance to chlorides and acids.

Wall Thickness: The wall thickness of the pipe is a critical factor that determines its ability to withstand pressure and temperature. Pipes with thicker walls are required for high-pressure or high-temperature systems, such as in the oil and gas industry. Ensure the thickness is selected based on the specific requirements of the system to avoid pipe failure.

Length and Diameter: The length and diameter of the pipe should fit within the system's constraints. For new installations or replacements, ensuring the pipe meets the required dimensions is essential for seamless integration into the system. A correctly sized pipe ensures proper flow and avoids complications during installation or operation.

Pricing and Procurement Strategies for Stainless Steel Seamless Pipes

Factors Influencing Stainless Steel Pipe Pricing

The cost of stainless steel seamless pipes is influenced by several factors:

Material Costs: Higher-grade stainless steel alloys (e.g., 316) tend to be more expensive due to their enhanced corrosion resistance and strength.

Wall Thickness: Pipes with thicker walls or larger diameters require more material and labor to manufacture, raising the cost.

Manufacturing Process: The complexity of the manufacturing process, such as hot extrusion and cold drawing, can increase the price.

Global Supply Chain and Supplier Selection Tips

When sourcing stainless steel seamless pipes, it’s important to choose reliable suppliers with a proven track record of quality and timely delivery. Ensure that the suppliers you choose comply with industry standards and have the necessary certifications. Establishing long-term relationships with trusted suppliers can also streamline procurement and reduce costs. Zhencheng Steel Co., Ltd. is a trusted supplier known for delivering high-quality seamless pipes that meet industry standards and exceed customer expectations.

How to Balance Quality and Cost-Effectiveness

While it’s tempting to choose the lowest-cost option, investing in high-quality stainless steel pipes will ultimately save money in the long run. High-quality pipes offer better performance, durability, and fewer maintenance requirements, which reduces the risk of failures, repairs, and downtime.

Conclusion

Stainless steel seamless pipes play a critical role in various industries due to their strength, corrosion resistance, and high-performance capabilities. It's important to choose the right material, wall thickness, and adhere to industry standards to ensure optimal pipe performance and longevity.

By investing in high-quality seamless pipes, industries can enjoy increased system durability and reduced maintenance costs. This ultimately leads to better operational efficiency.

Zhencheng Steel Co., Ltd. offers seamless pipes known for their exceptional durability and high performance, providing significant value for industries across different sectors. Their products help ensure the safety and reliability of systems, minimizing downtime and enhancing overall productivity.

FAQ

Q: What is a Stainless Steel Seamless Pipe?

A: A Stainless Steel Seamless Pipe is a pipe made from a single solid billet of stainless steel, formed without any welding. This method creates a uniform structure, making the pipe ideal for high-pressure and high-temperature environments.

Q: Why are Stainless Steel Seamless Pipes preferred in industrial applications?

A: Stainless Steel Seamless Pipes are preferred for their strength, corrosion resistance, and ability to withstand high pressures. These qualities make them ideal for use in industries such as oil and gas, chemical processing, and power generation.

Q: How do I choose the right Stainless Steel Seamless Pipe?

A: When choosing a Stainless Steel Seamless Pipe, consider factors like material grade (e.g., 304 or 316), wall thickness, and pipe size. Ensure the pipe meets industry standards like ASTM or EN based on your application’s requirements.

Q: What are the advantages of Stainless Steel Seamless Pipes over welded pipes?

A: Stainless Steel Seamless Pipes offer better strength, higher pressure tolerance, and enhanced resistance to corrosion compared to welded pipes, as they don’t have weak spots caused by welding seams.

Q: How is the cost of Stainless Steel Seamless Pipes determined?

A: The cost of Stainless Steel Seamless Pipes depends on factors like material grade, pipe size, wall thickness, and manufacturing process. Higher-quality alloys and thicker pipes tend to cost more due to the increased material and production requirements.