Our heat exchanger tubes are engineered for superior thermal conductivity, corrosion resistance, and durability in demanding industrial environments. Manufactured under strict international standards (ASTM, ASME, EN, GB), our tubes ensure reliable performance in oil & gas, power plants, chemical processing, HVAC, and marine applications.

Applications:

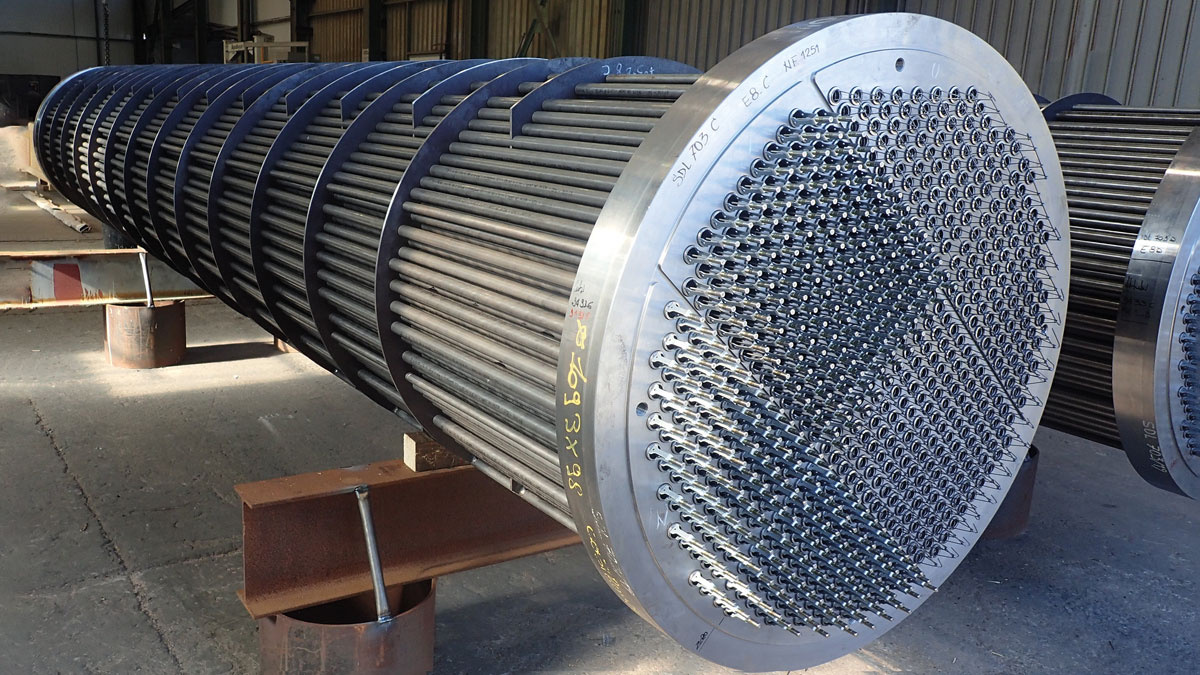

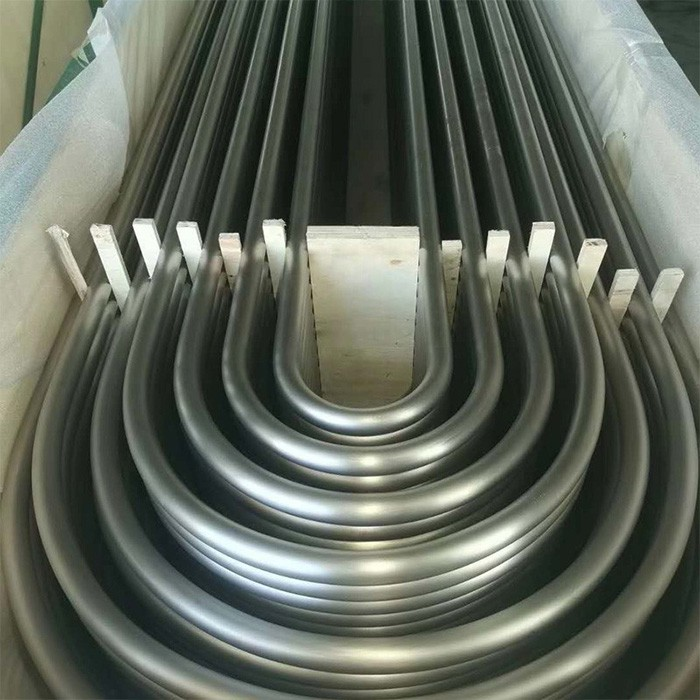

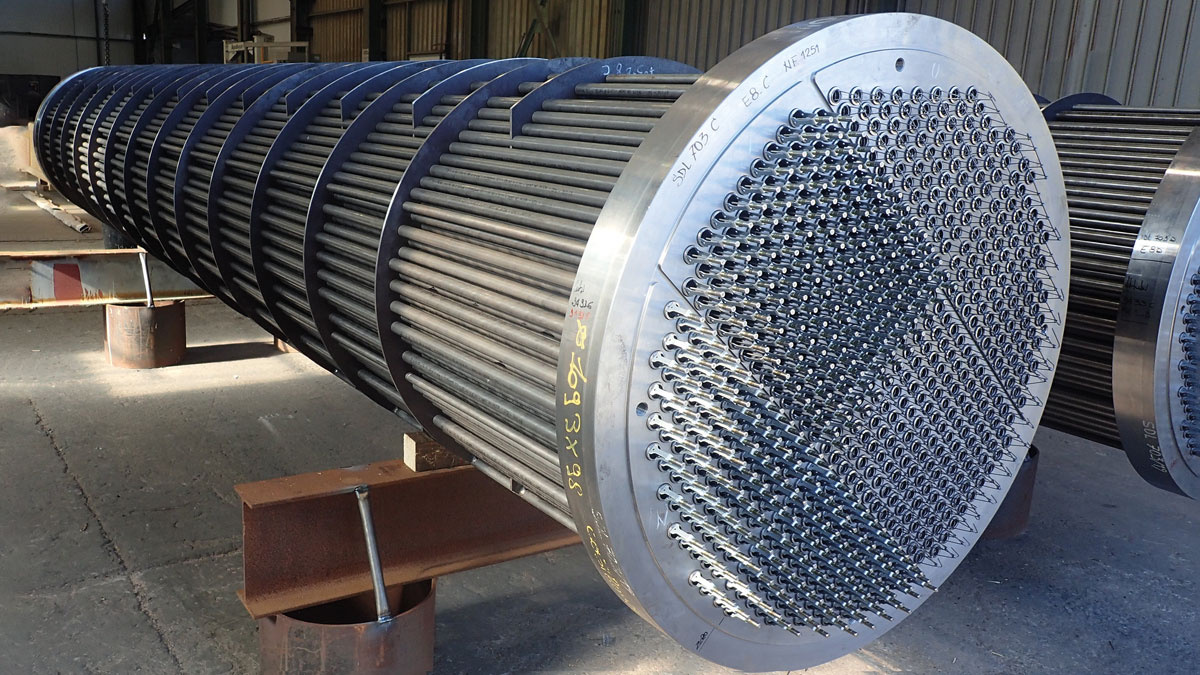

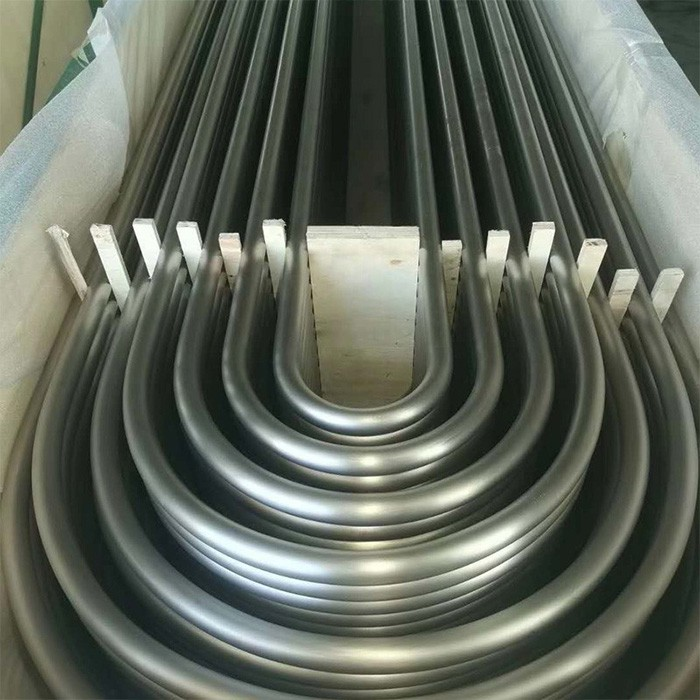

Shell & tube heat exchangers

Condensers & evaporators

Boilers & feedwater heaters

Oil coolers & process heaters

Power plant equipment

Available Materials & Steel Grades

1. Carbon Steel Tubes

ASTM A179 – Cold-drawn seamless tubes for low-pressure heat exchangers.

ASTM A192 – High-pressure boiler & heat exchanger applications.

ASTM A106 Gr.B – Ideal for steam and high-temperature services.

2. Stainless Steel Tubes

304/304L, 316/316L (ASTM A312) – Excellent resistance to acids, alkalis, and chlorides.

Duplex Stainless Steel (2205, UNS S31803) – Superior strength and chloride resistance for offshore & chemical industries.

3. Nickel Alloy Tubes

Inconel 600/625, Hastelloy C276 – Extreme corrosion & high-temperature resistance (up to 1200°C).

Monel 400 – Ideal for seawater and hydrofluoric acid environments.

4. Copper & Copper Alloy Tubes

Copper (ASTM B111), Cu-Ni (90/10, 70/30) – High thermal conductivity for HVAC and marine condensers.

5. Titanium Tubes (Gr.2, Gr.5)

Lightweight, highly corrosion-resistant, perfect for desalination, chemical processing, and offshore applications.

Standard Sizes & Specifications

Parameter Range

Outer Diameter (OD) 6mm – 50mm (Seamless), Up to 150mm (Welded)

Wall Thickness 0.5mm – 10mm

Length 1m – 12m (Custom lengths available)

Standards ASTM, ASME, EN, DIN, JIS, GB

Advanced Manufacturing Process:

Material selection & inspection

Tube forming (seamless or welded)

Cold drawing/pilgering for dimensional accuracy

Heat treatment (annealing, solution treatment)

Surface finishing (pickling, polishing)

Cutting to length

Final inspection and testing

Quality Control & Testing:

Chemical composition analysis

Mechanical property testing (tensile, hardness)

Hydrostatic/pneumatic pressure testing

Non-destructive testing (UT, ET, RT)

Dimensional inspection (OD, WT, straightness)

Surface quality inspection

PMI (Positive Material Identification)

Key Features & Benefits

✔ High Thermal Efficiency – Optimized for maximum heat transfer.

✔ Corrosion-Resistant Materials – Extended service life even in harsh conditions.

✔ Custom Sizes & Specifications – Tailored to meet your project requirements.

✔ Strict Quality Control – Fully tested for pressure, dimensional accuracy, and material integrity.