Nostrum calor exchanger fistulae sunt machinatum pro superior scelerisque conductivity, corrosio resistentia, et diuturnitatem et postulant industriae environments. Product in stricte Internationalis signa (ASM, ASME, en, GB), nostri tubulis curare reliable perficientur in oleum & Gas, potentia plantis, eget dispensando, HVAC, et Marine Applications.

Applications:

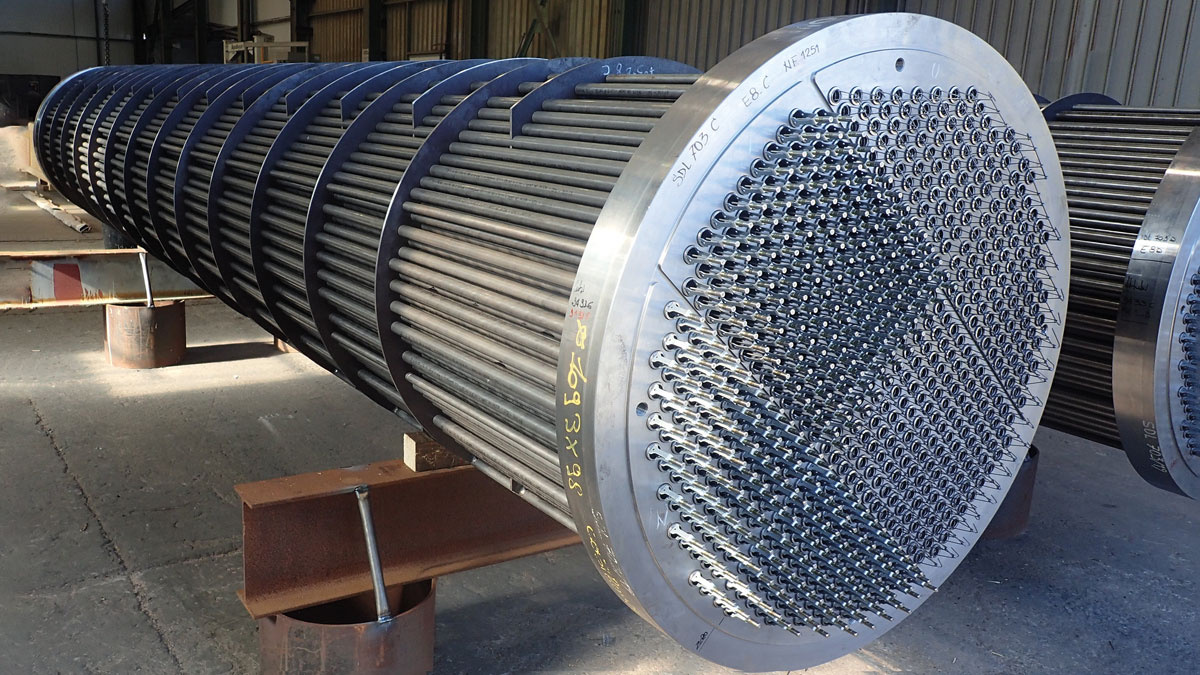

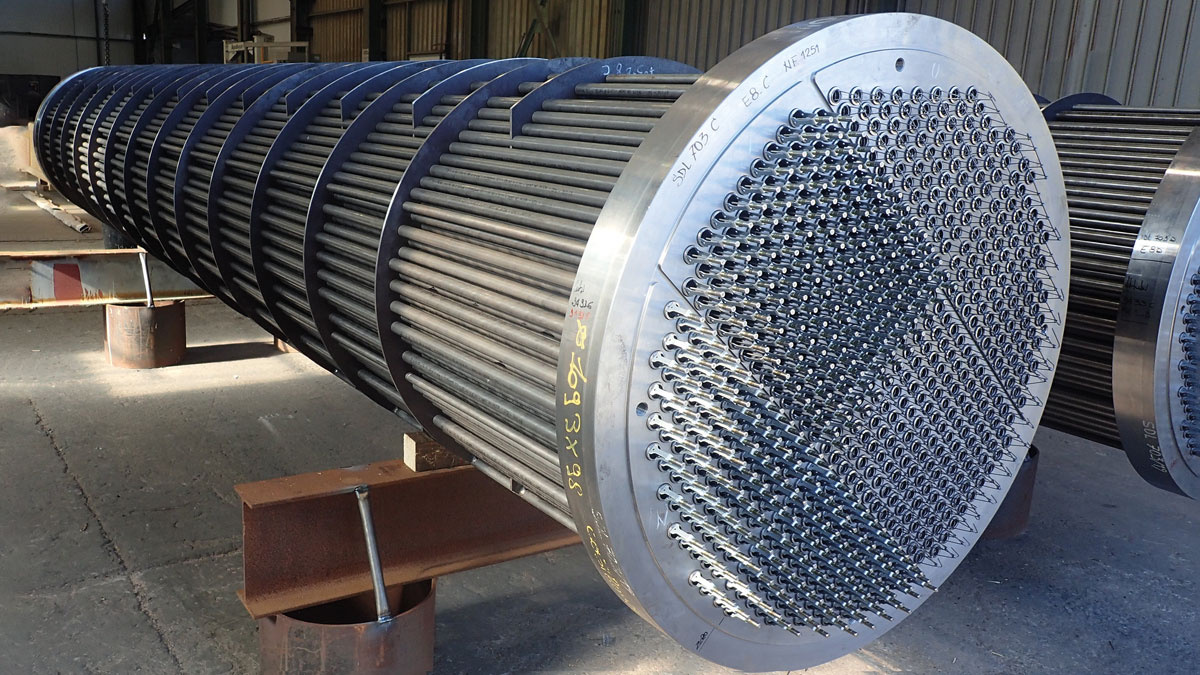

Crusta & Tube Mundi Convhangers

Condensers & evaporators

Boilers & Feedwater Fortuna

Oleum Coolers & Processus Heaters

Planta Plant Equipment

Available Materials & Steel Grades

I. Carbon Steel Tubes

ASTM A179 - Frigus-Traipsae Tubes enim humilis-pressionem calor deicit.

ASTM A192 - High-pressura Boiler & calor exchanger Applications.

ASTM A106 GR.B - Specimen pro Vapor et High-Temperature Services.

II. Steel tubulis immaculatam

CCCIV / 304L, CCCXVI / 316L (ASTM A312) - optimum resistentia ad acida, alkalis et chlorides.

Duplex Aliquam Steel (MMCCV, uns S31803) - Superior Fortitudo et Chloride Repugnantia enim Offshore & eget Industria.

III. Nickel Alloy Tubes

Inconel 600/625, C276 EXERCENDI - Extreme Corrosio & High-Temperature resistentia (usque ad MCC ° C).

Monel CD - Specimen pro searchater et hydrofluoric acidum environments.

IV. Aeris & aeris Alloy Tubes

Aeris (ASTM B111), Cu-NI (90/10, 70/30) - High scelerisque conductivity pro HVAC et Marine Condensers.

V. Titanium tubulis (Gr.2, Gr.5)

Lightweight, altus corrosio repugnans, perfectum pro desalination, eget dispensando, et offshore applications.

Latin Sizes & Specifications

Parameter range

Diameter exterius (OD) 6mm - 50mm (seamless), usque ad 150mm (Welded)

Wall Crassitudo 0.5mm - 10mm

Longitudo 1m - 12m (Custom longitudines praesto)

Standards ASTM, ASME, en, Laudate, Jis, GB

Advanced Manufacturing Processus:

Material Electio & Inspectionem

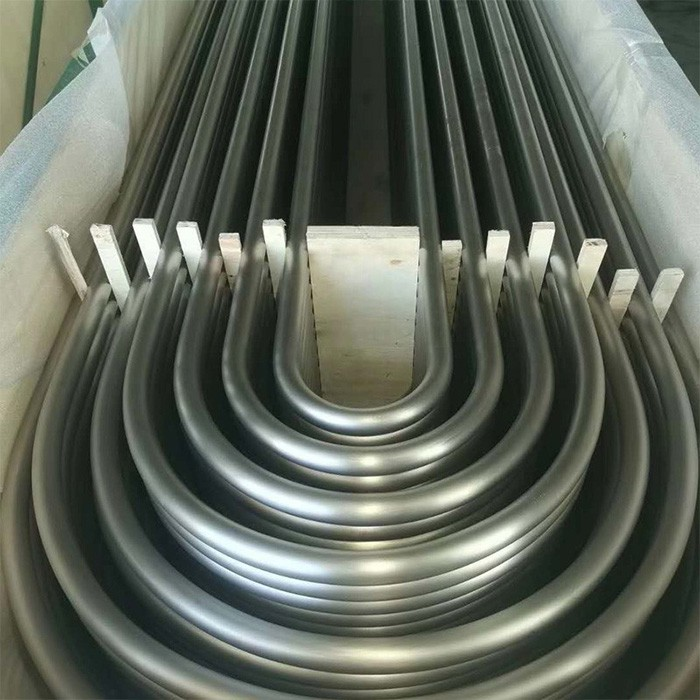

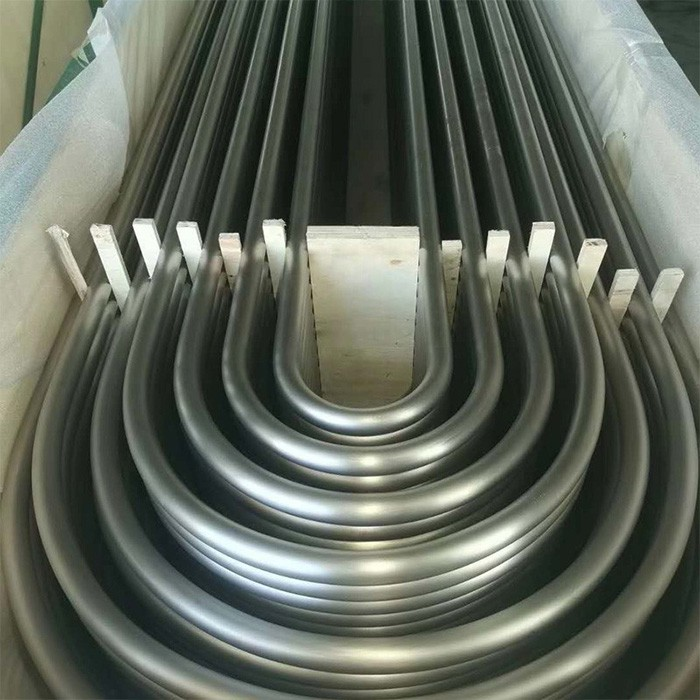

Tube formans (seamless aut welded)

Frigus drawing / Papor enim dimensional accurate

Calor curatio (Annealing, solution Treatment)

Superficies consummatione (Pickling, Polising)

Tandem secans

Finalis inspectionem et testis

Qualis Imperium & Testing:

Chemical Compositionem Analysis

Mechanica proprietas temptationis (tensile, duritia)

Hydrostatic / Pneumatic pressura temptationis

Non-perniciosius testis (UT, et, RT)

Dimensional inspectionem (Od, cum, rectitudo)

Superficiem species inspectionem

PMI (positivum materia idem)

Key Features & Benefits

✔ High scelerisque efficientiam - optimized ad maximum calor translatio.

✔ Corrosion-repugnant materiae - extenditur servitium vitae etiam in dura conditionibus.

✔ Custom Sizes & Specifications - Tailored in occursum tuum project elit.

✔ stricte qualitas imperium - plene probata pressura, dimensional accurate et materialium integritas.