Applicationem Casting & Tubing

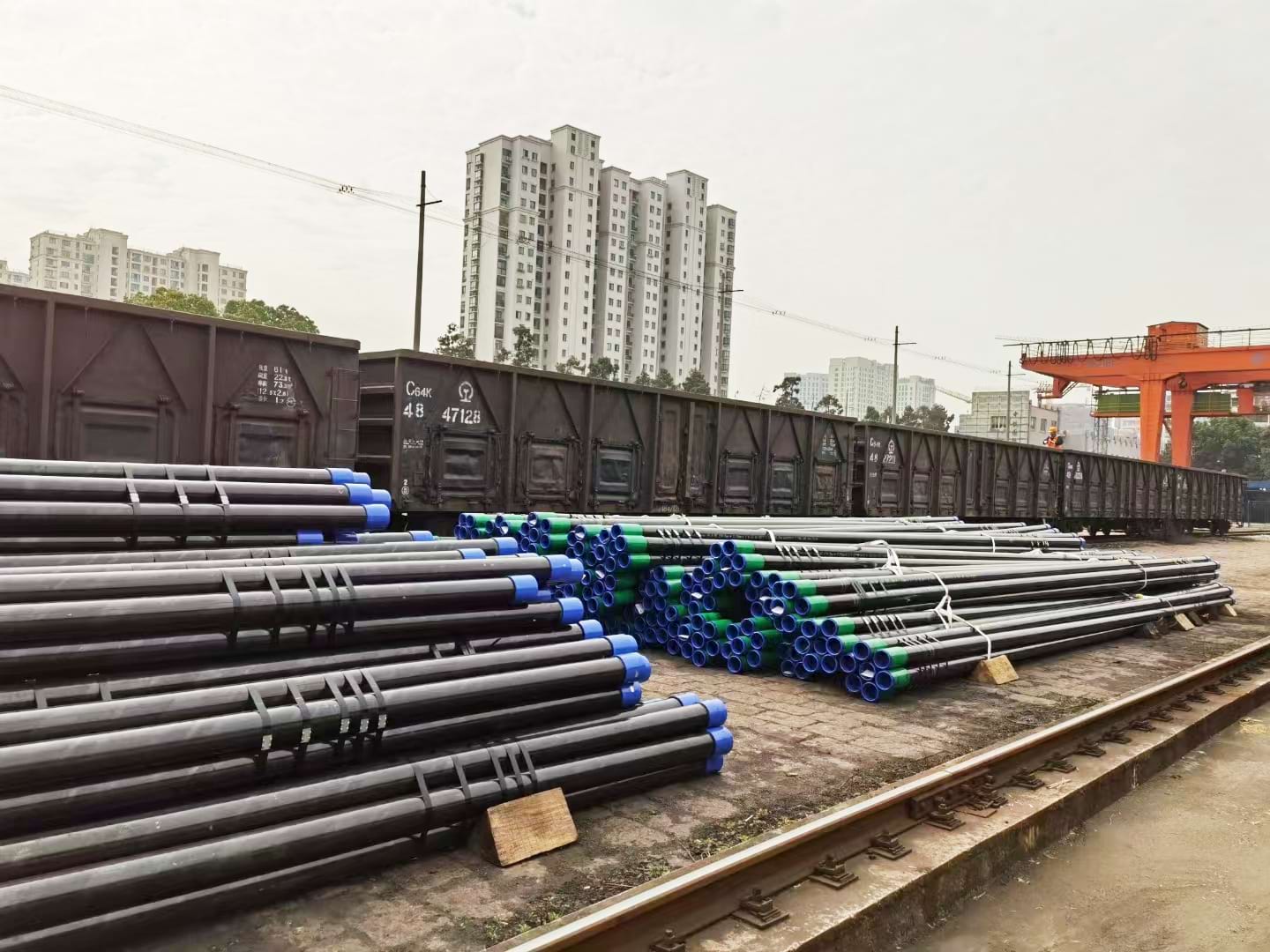

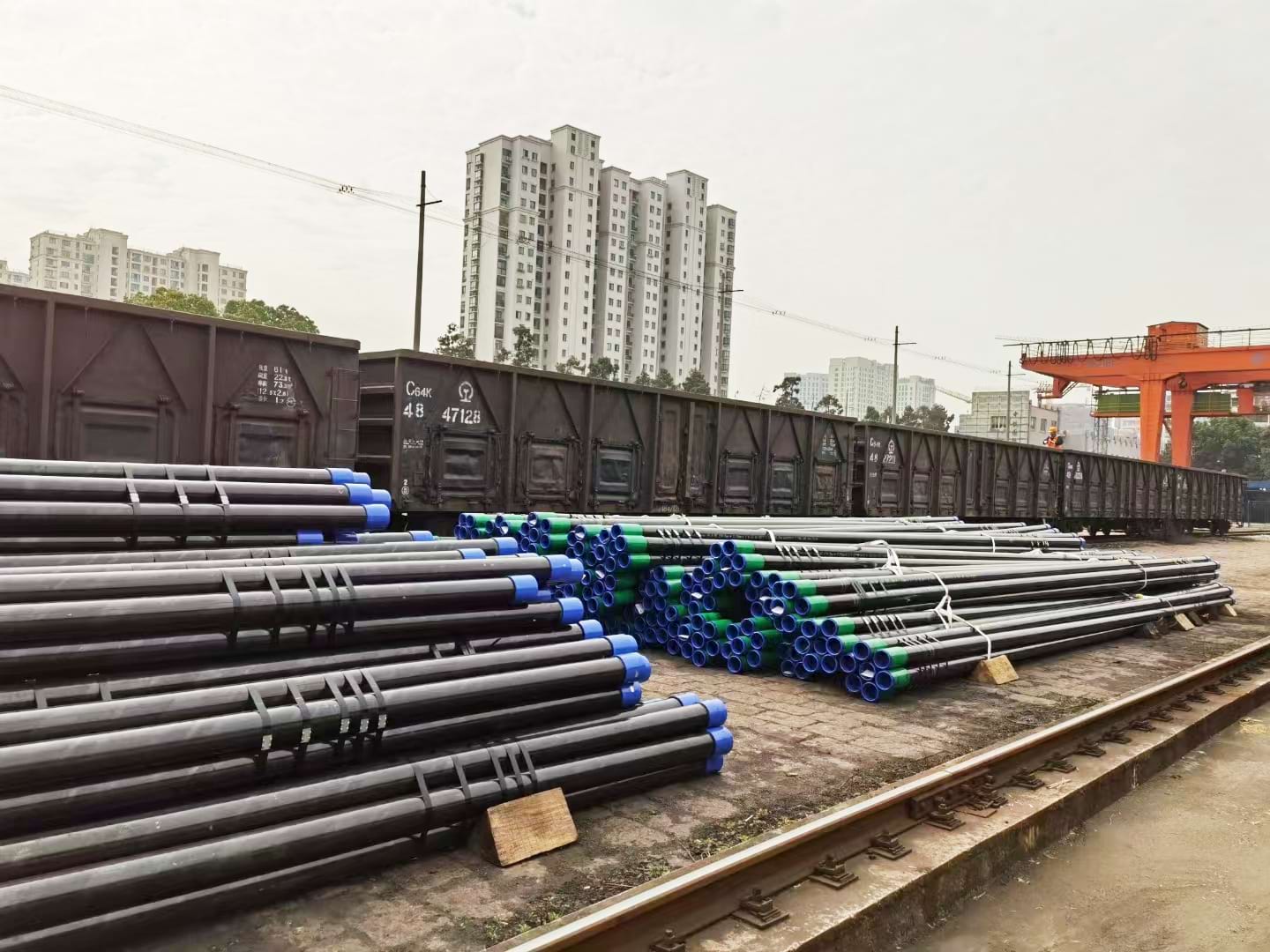

Oil casing steel pipes are specialized pipes used in the oil and gas industry for drilling, completing, and producing oil and natural gas wells,which are typically made of high-strength carbon or alloy steel and come in various sizes and dimensions to suit different well specifications.

Oleum Tubing Steel Pipes est genus ferro pipe disposito extractionem olei et Gas ex Wells, quae sunt maxime in productio phase olei et naturalis Gas Pipes, cum minor Diametri comparari Casting. Tubing Pipes sunt installed intra atram tibiarum et extend a flowhead imo bene serve sicut conditiones ad translationem oleum naturalis Gas et fluidorum.

Specifications de casings

Od: 4.5 '' ad XX ''

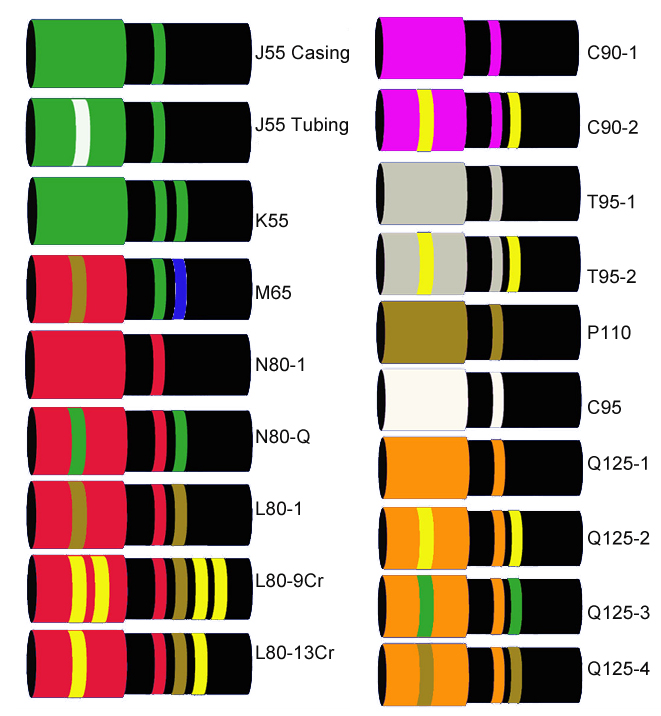

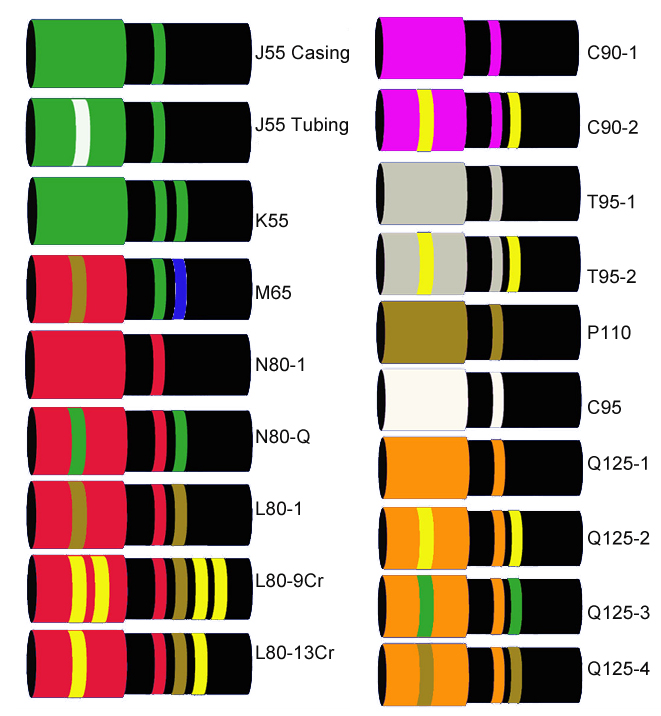

Grade: J55, K55, N80, L80, P110, Q125, V150, L80-1CR L80-3CR, L80-9CR, L80-13CR

Standard: API DCT

Connection: P (patet finem), STC (brevis relatorum), LTC (Long Sequelae), BTC (Buttress Sequelae) Premium Connection

Longitudo: Range3

Product Specification Level: PSL1, PSL2, PSL3

Specifications Tubations

Od: 1.9 '' ad 4.5 ''

Grade: J55, K55, N80, L80, P110, Q125, V150, L80-1CR L80-3CR, L80-9CR, L80-13CR

Standard: API DCT

Connection: Non-perturbatus terminos (nue), externa perturbatus terminos (Eue) Premium Connection

Longitudo: Range2

Product Specification Level: PSL1, PSL2, PSL3

Color anulum in Casting & Tubing

Sulfur ROSIO resistant & High collapse Casting et Tubing

Sulphur corrosio-repugnant et altus-collapse armamentis et Tubing sunt specialioribus materiae in oleum et Gas industria, praecipue in environments ubi princeps campester of sulphuris sunt. Hi materiae typically factum ex speciali Alloys qui sunt altus repugnant ad corrosio coram sulphuris componit. Commune Alloys includit Chromium, Nickel et Molybdenum.

Grades of Chrome Casting & Tubing: 1CR, 3Cr, 9CR, 13CR, super 13CR (Chrome, I% C, III% C, IX% CR, XIII%)

Grades de sulphuris corrosio repugnant armamentis & Tubing: 80ss, 95ss, 100ss, 110ss

Grades de High collapse Creating & Tubing: 80HC, 95HC, 110HC, 125HC, 140HC

* Technical cum clients ad occursum diversis demanda materiae

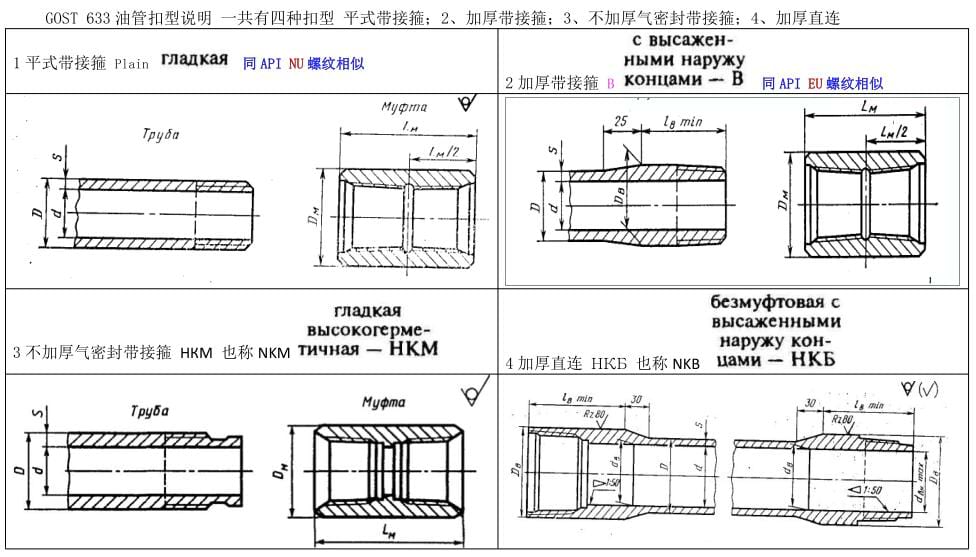

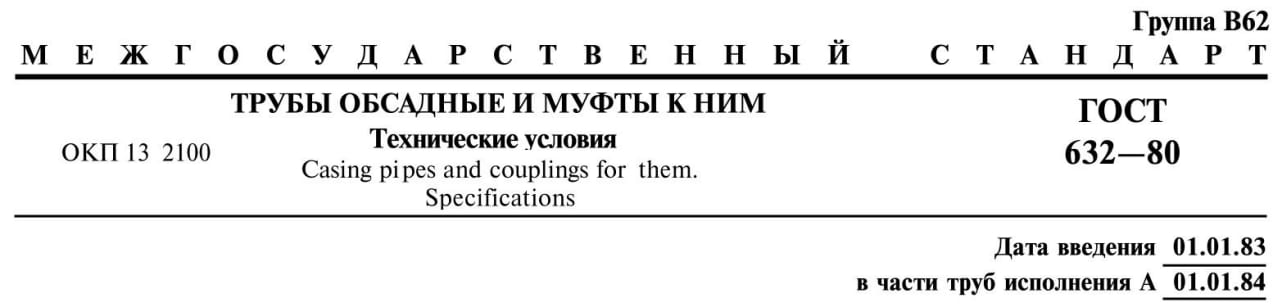

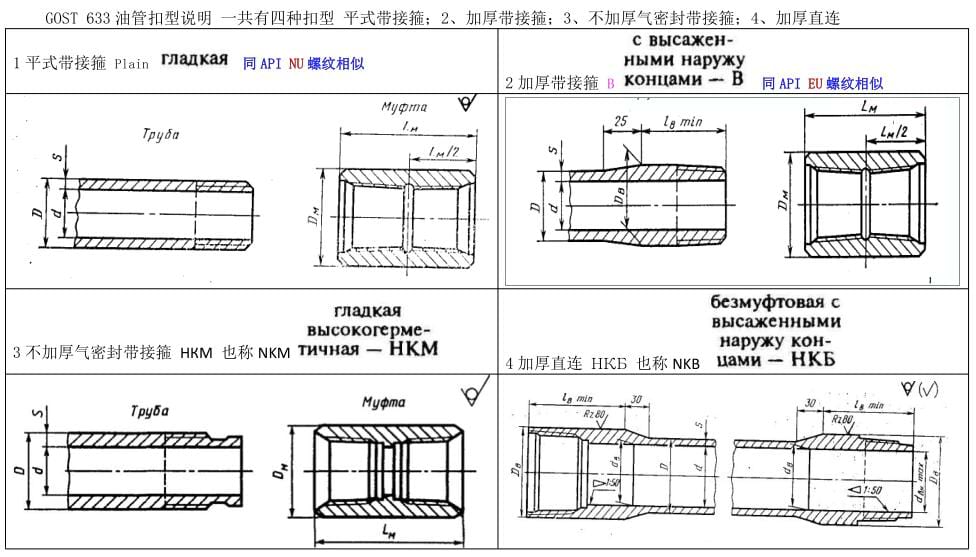

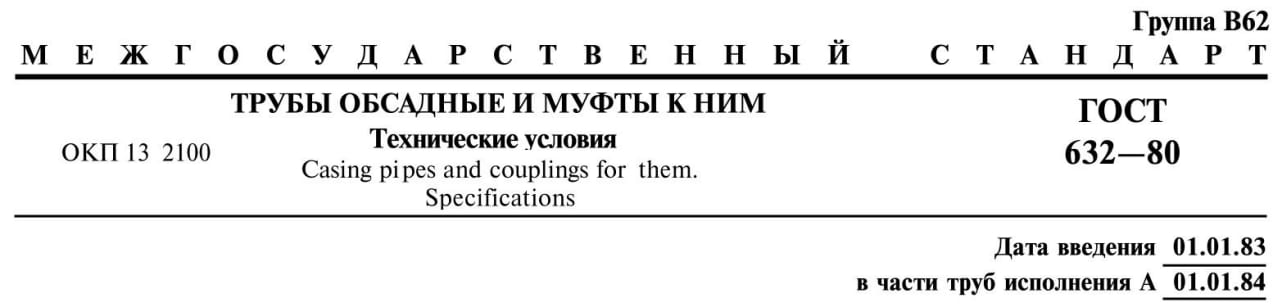

Gostus Casting & Tubing

Goste vexillum (DCXXXII Gostae, DCXXXIII, Gostae DCXXXIII, (VIII) DCXLV Gostae) vexillum Creing & Tubing maxime usus a Medio Asian terris.

Connection:

Creing: Ottm & Ottg

Tubing: Nu & EU