Cásáil agus feadánra a chur i bhfeidhm

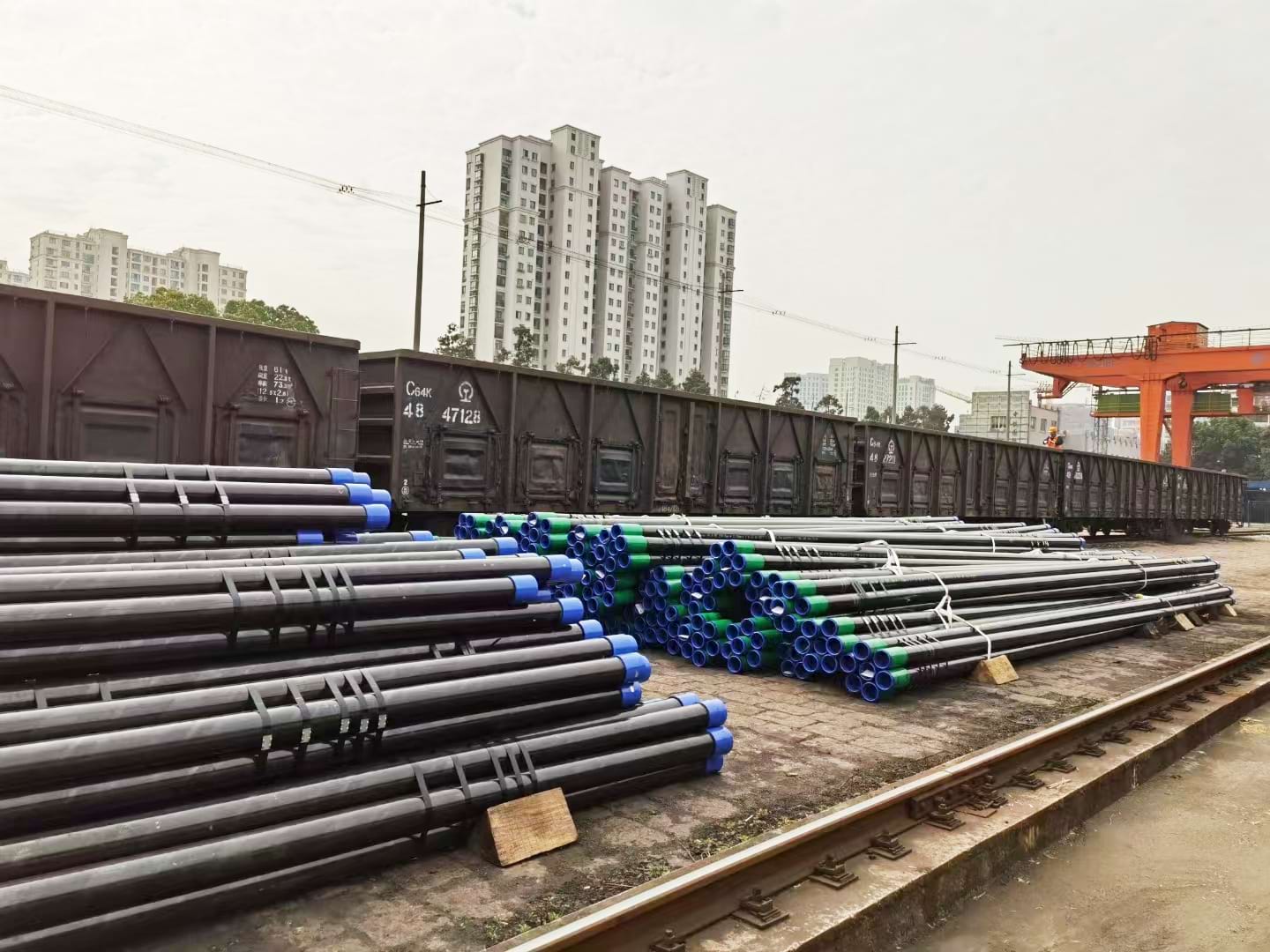

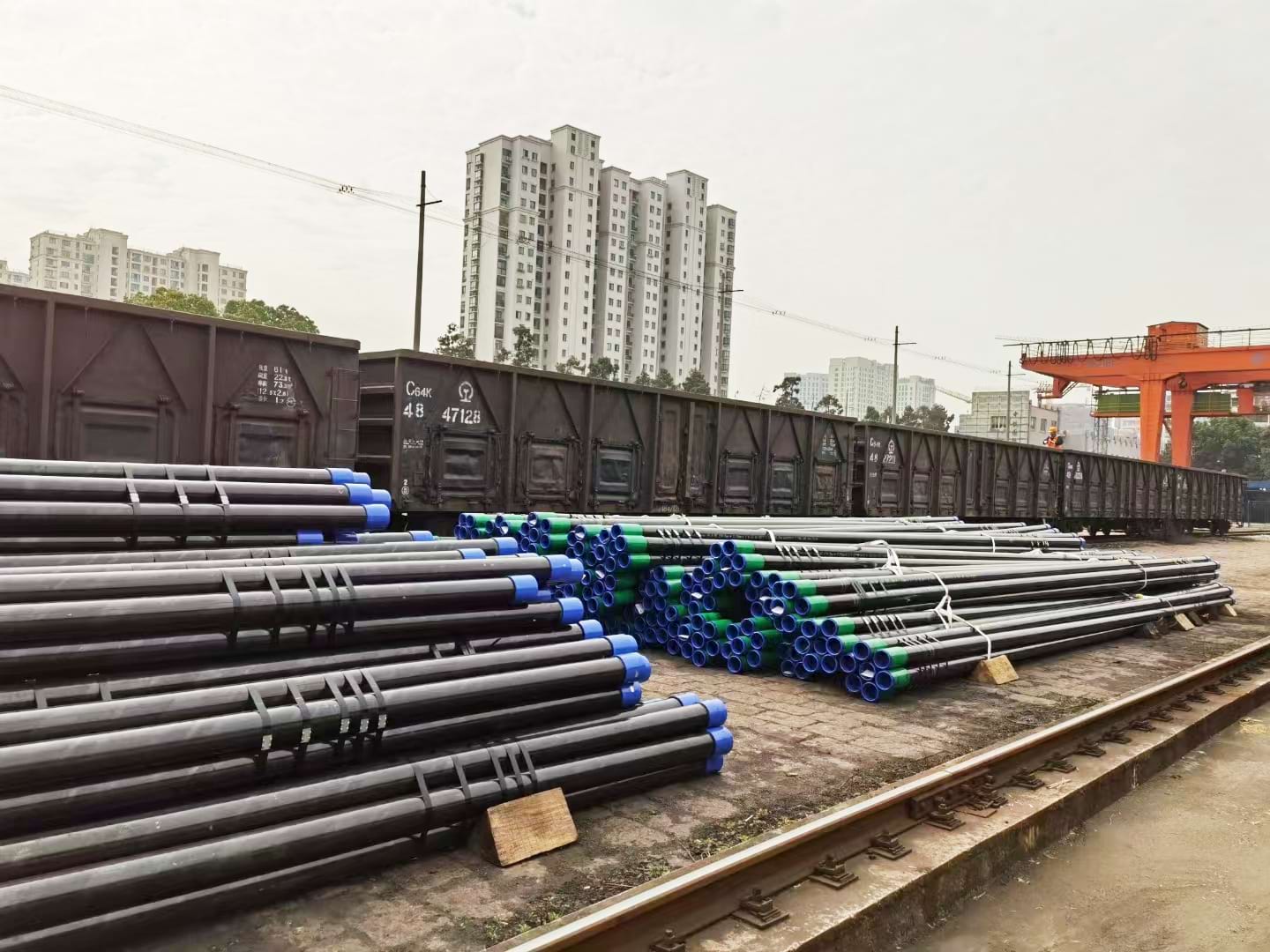

Is píopaí speisialaithe iad píopaí cruach ola a úsáidtear sa tionscal ola agus gáis chun toibreacha ola agus gáis nádúrtha a dhruileáil, a chomhlánú agus a tháirgeadh, a dhéantar de ghnáth as cruach charbóin nó cóimhiotail ard-neart agus a thagann i méideanna agus toisí éagsúla a oireann do shonraíochtaí éagsúla.

Is cineál píopa cruach é píopaí cruach feadánra ola atá deartha chun ola agus gáis a bhaint as toibreacha, a úsáidtear go háirithe i gcéim táirgthe toibreacha ola agus gáis nádúrtha, le trastomhais níos lú i gcomparáid le píopaí cásála. Tá píopaí feadánra suiteáilte taobh istigh de phíopaí casing agus síneann siad ón toibreacha go bun an tobair, feidhmíonn siad mar sheoladáin chun ola, gás nádúrtha, agus sreabháin eile a iompar.

Sonraíochtaí casings

OD: 4.5 '' go 20 ''

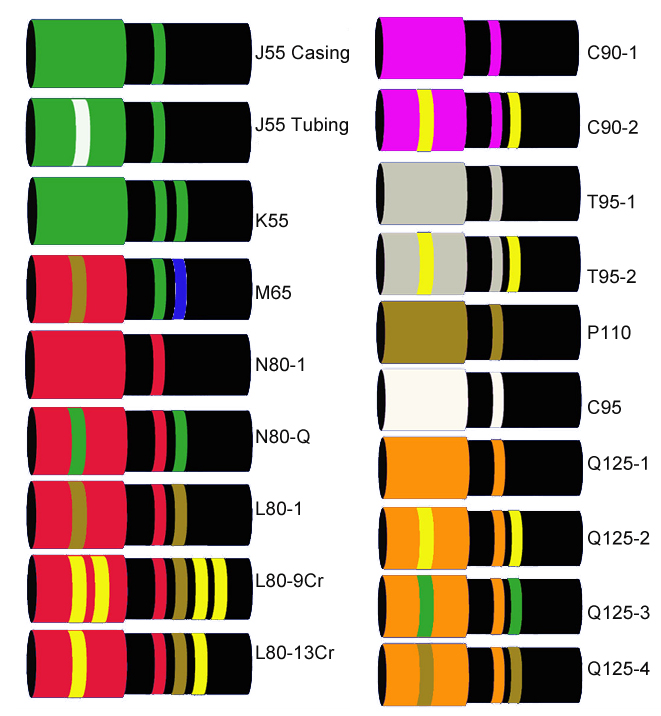

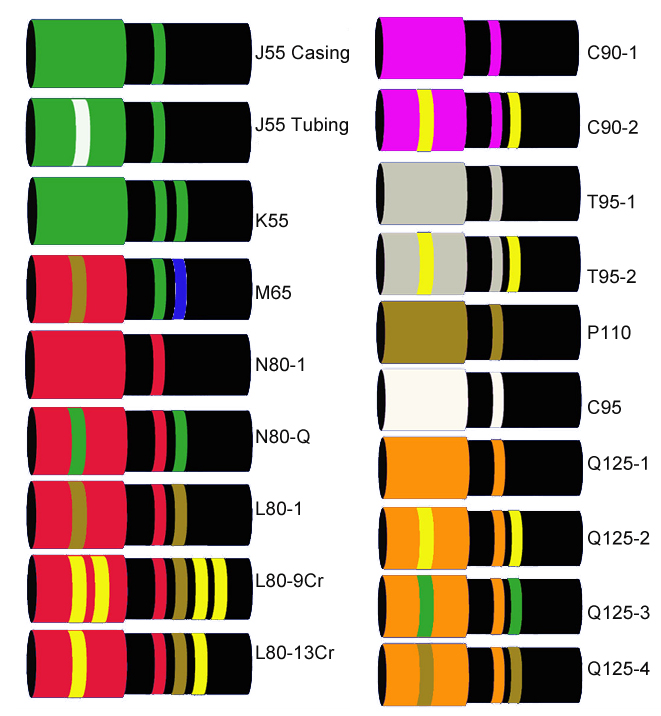

Grád: J55, K55, N80, L80, P110, Q125, V150, L80-1CR, L80-3CR, L80-9CR, L80-13CR

Caighdeán: API 5CT

Nasc: P (deireadh plain), STC (snáitheanna gearra), LTC (snáitheanna fada), BTC (snáitheanna buttress), nasc préimhe

Fad: raon3

Leibhéal Sonraíochta Táirgí: PSL1, PSL2, PSL3

Sonraíochtaí na dTiúrtha

OD: 1.9 '' go 4.5 ''

Grád: J55, K55, N80, L80, P110, Q125, V150, L80-1CR, L80-3CR, L80-9CR, L80-13CR

Caighdeán: API 5CT

Nasc: Críocha neamhshrianta (NUE), Ceangal Préimh Seachtrach (EUE) Ceangal Préimh Seachtrach (EUE)

Fad: raon2

Leibhéal Sonraíochta Táirgí: PSL1, PSL2, PSL3

Fáinne daite ar chásáil & feadánra

Casáil agus feadánra agus feadánra ard -titim creimthe sulfair agus

Is ábhair speisialaithe iad cásáil agus feadánra atá frithsheasmhach in aghaidh agus creimeadh sulfair agus a úsáidtear sa tionscal ola agus gáis, go háirithe i dtimpeallachtaí ina bhfuil leibhéil arda sulfair i láthair. Is iondúil go ndéantar na hábhair seo as cóimhiotail speisialta atá an -fhrithsheasmhach in aghaidh creimthe i láthair comhdhúile sulfair. I measc na gcóimhiotail choitianta tá cróimiam, nicil, agus moluibdín.

Gráid de chásáil chrome & feadánra: 1CR, 3CR, 9CR, 13CR, Super 13CR (Chrome, 1%CR, 3%CR, 9%CR, 13%)

Gráid de chásáil agus feadánra frithsheasmhach in aghaidh creimthe sulfair: 80ss, 95ss, 100ss, 110sss

Gráid de chásáil ard -titim & feadánra: 80hc, 95hc, 110hc, 125hc, 140hc

*Ar chomhaontú teicniúil le cliaint chun freastal ar éileamh difriúil ar ábhair

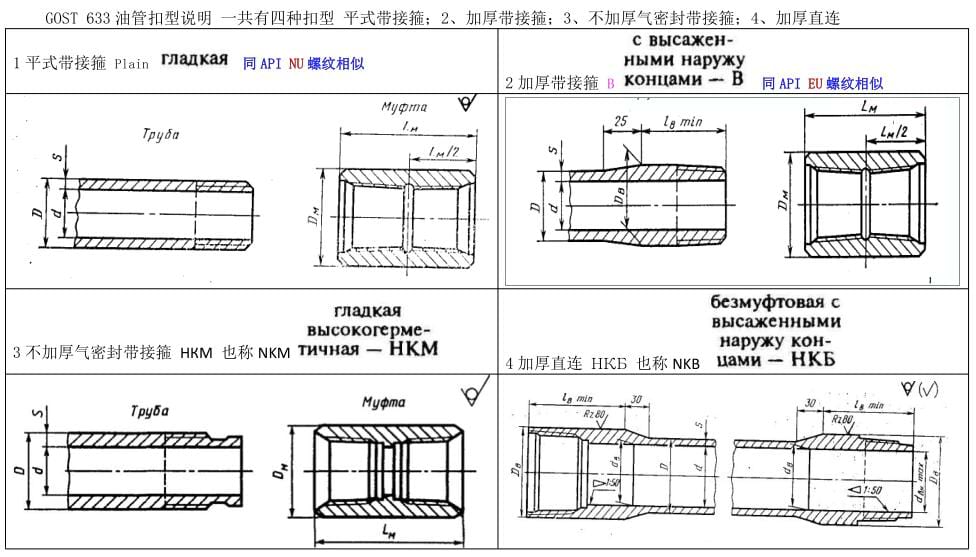

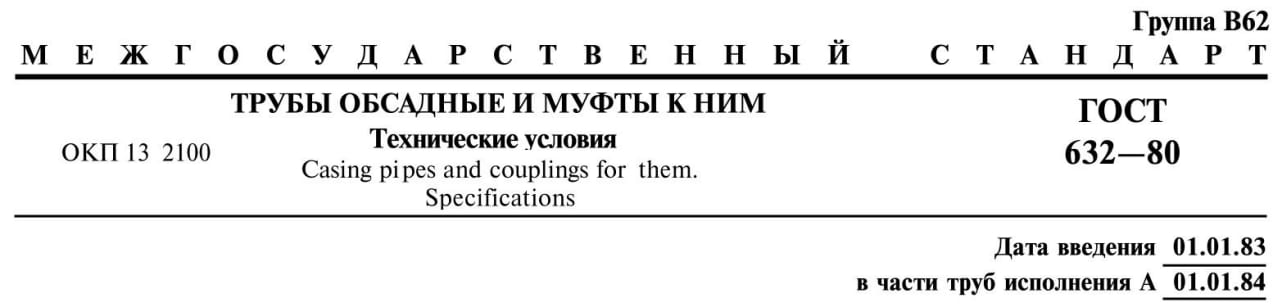

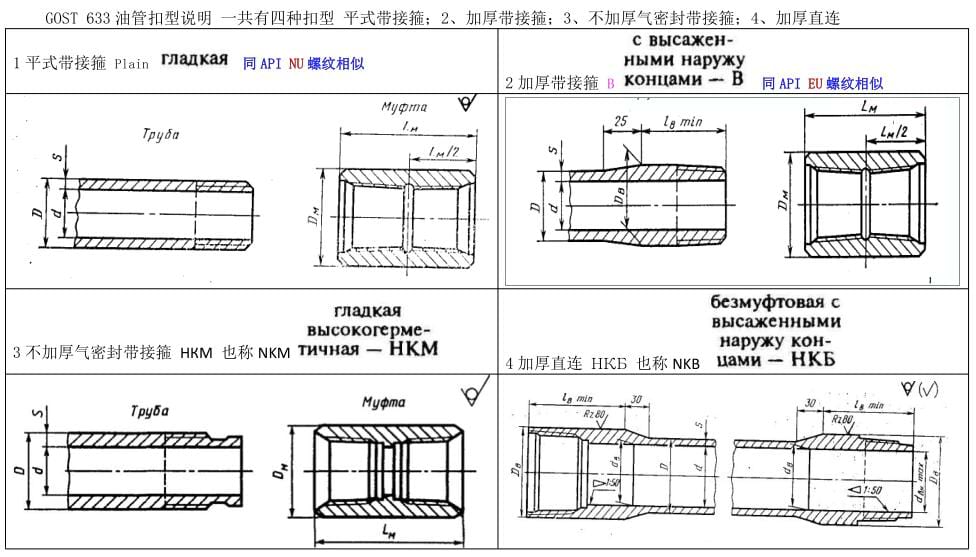

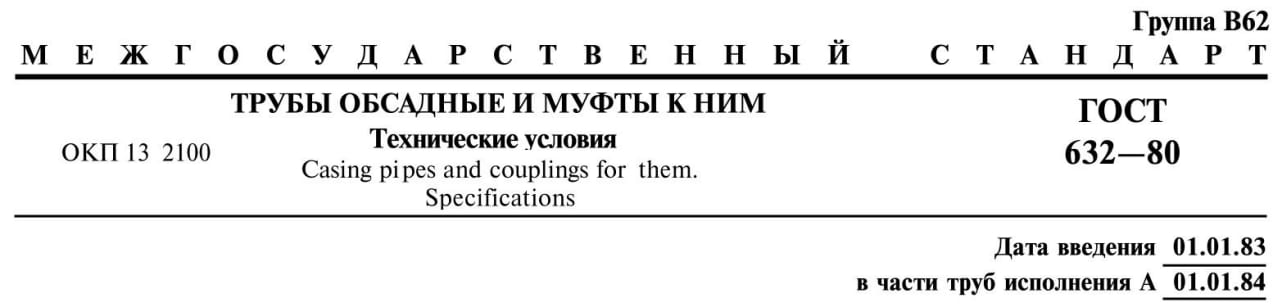

Cásáil agus feadánra gost

Is é an caighdeán GOST (GOST 632, GOST 633, GOST 8645) caighdeán an chásála agus an fheadáin a úsáideann tíortha na hÁise Mheán -na hÁise den chuid is mó.

CANDÚ:

Cásáil: Ottm & Ottg

Feadánra: Nu & AE