Toepassing van omhulsel en buise

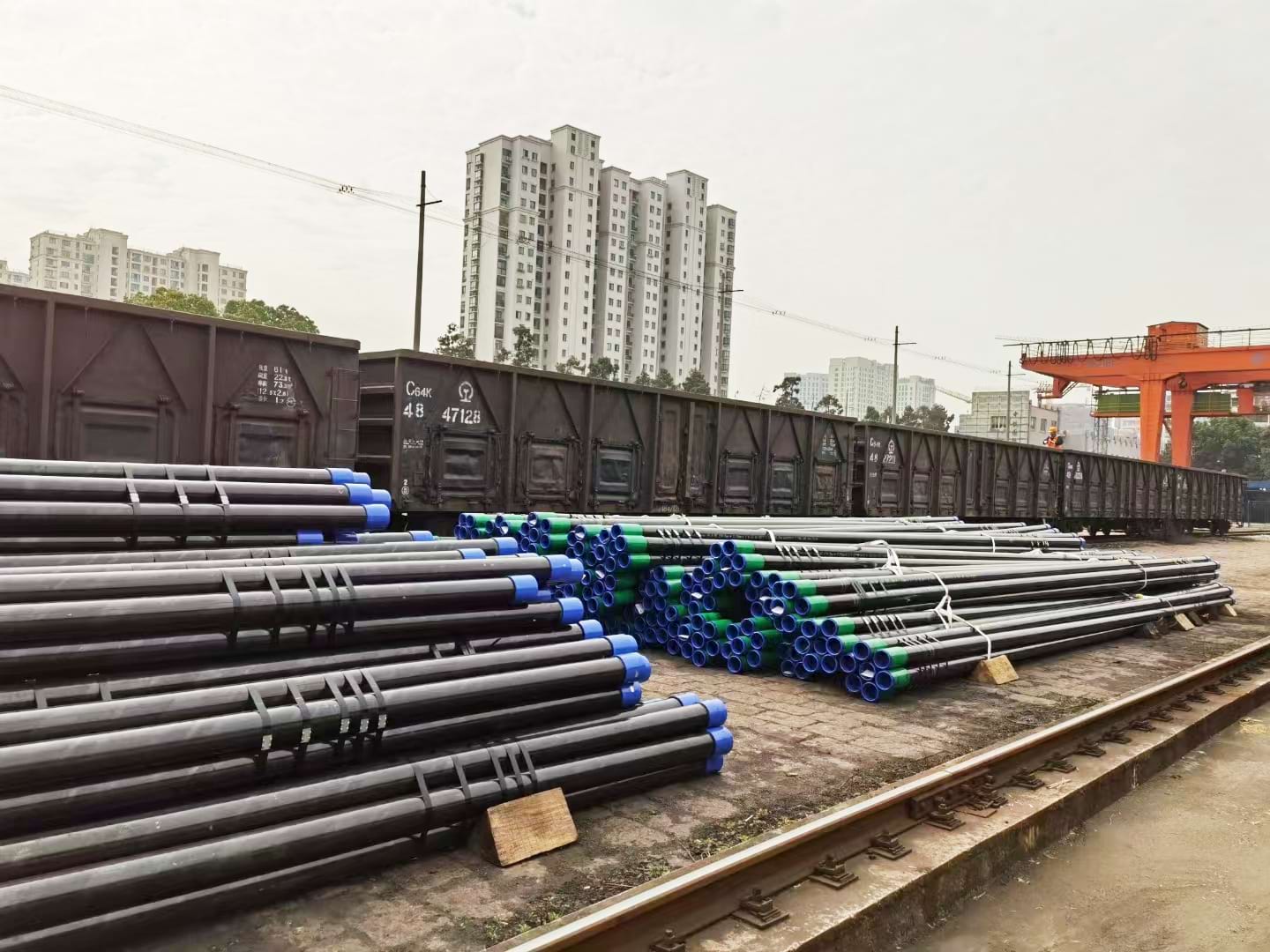

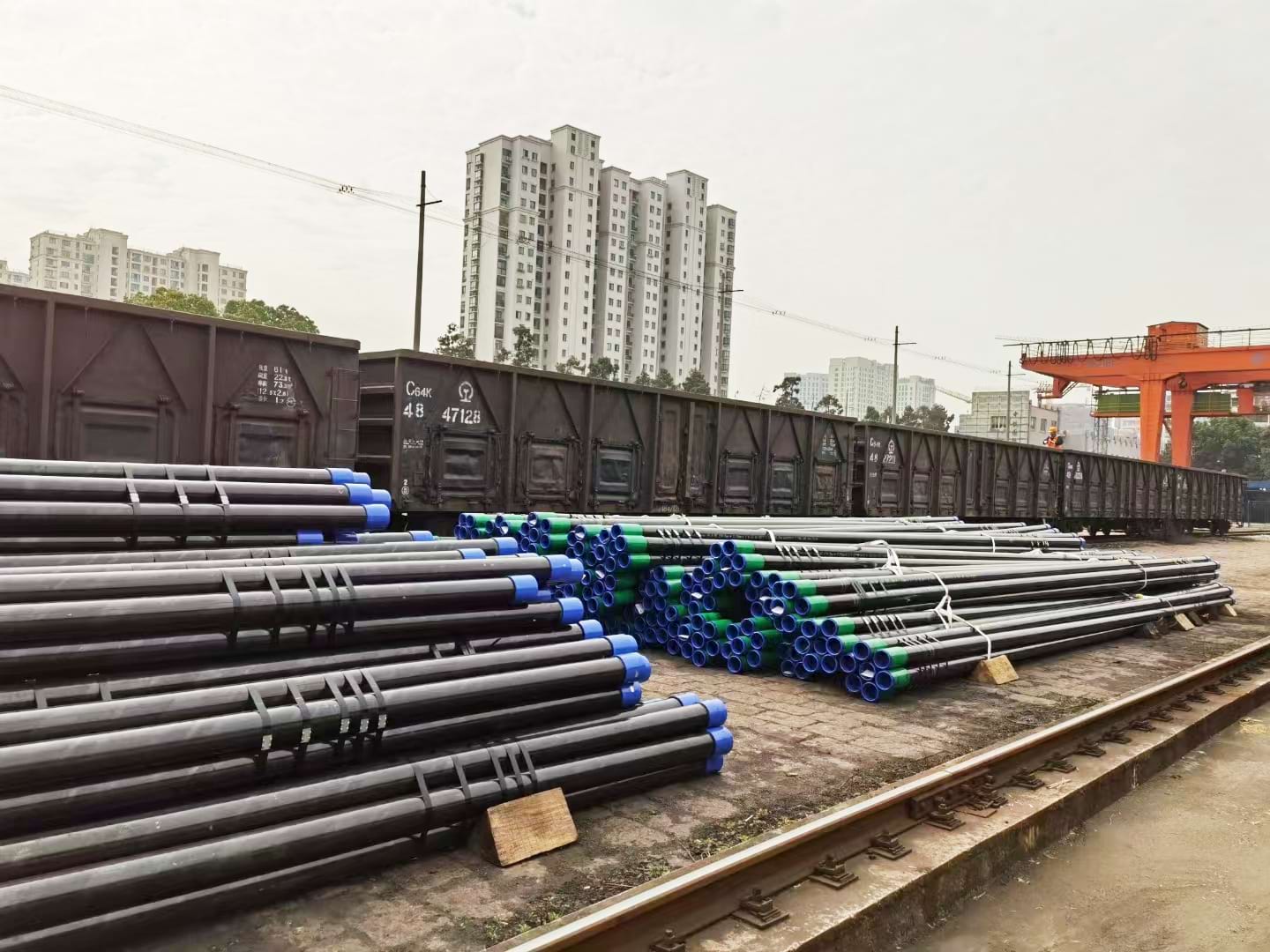

Die olie-omhulselstaalpype is gespesialiseerde pype wat in die olie- en gasbedryf gebruik word vir die boor, voltooiing en vervaardiging van olie- en aardgasputte, wat tipies van koolstof- of legeringsstaal is en in verskillende groottes en afmetings bestaan om aan verskillende spesifikasies te pas.

Oliebuisstaalpype is 'n tipe staalpyp wat ontwerp is vir die ekstraksie van olie en gas uit putte, wat veral in die produksiefase van olie- en aardgasputte gebruik word, met kleiner diameters in vergelyking met omhulselpype. Buispype word in die omhulselpype geïnstalleer en strek van die boorkop na die onderkant van die put, dien as leidings voor vir die vervoer van olie, aardgas en ander vloeistowwe.

Spesifikasies van omhulsels

OD: 4.5 '' tot 20 ''

Graad: J55, K55, N80, L80, P110, Q125, V150, L80-1CR, L80-3CR, L80-9CR, L80-13CRCR

Standaard: API 5CT

Verbinding: P (gewone einde), STC (kort drade), LTC (lang drade), BTC (Buttress -drade), premiumverbinding

Lengte: Range3

Produkspesifikasievlak: PSL1, PSL2, PSL3

Spesifikasies van buisies

OD: 1.9 '' tot 4.5 ''

Graad: J55, K55, N80, L80, P110, Q125, V150, L80-1CR, L80-3CR, L80-9CR, L80-13CRCR

Standaard: API 5CT

Verbinding: nie-upset-eindes (NUE), eksterne ontstelde eindes (EUE) premiumverbinding

Lengte: Range2

Produkspesifikasievlak: PSL1, PSL2, PSL3

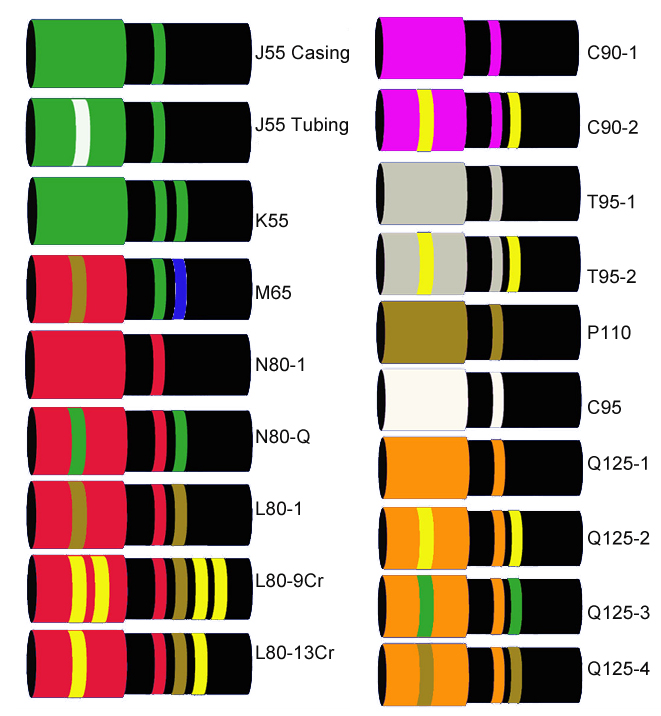

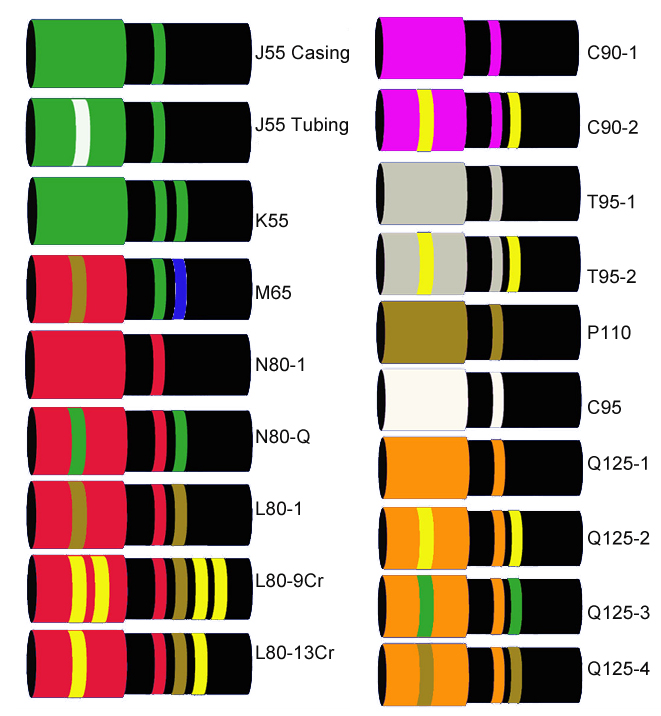

Kleurring op omhulsel en buise

Swael korrosiebestand en hoë ineenstorting omhulsel en buis

Swael-korrosiebestande en hoë-ineenstortingsomhulsel en buise is gespesialiseerde materiale wat in die olie- en gasbedryf gebruik word, veral in omgewings waar hoë vlakke van swael teenwoordig is. Hierdie materiale word tipies gemaak van spesiale legerings wat baie bestand is teen korrosie in die teenwoordigheid van swaelverbindings. Algemene legerings sluit in chroom, nikkel en molibdeen.

Graad chroomomhulsel en buise: 1CR, 3CR, 9CR, 13CR, Super 13CR (chroom, 1%Cr, 3%Cr, 9%Cr, 13%)

Grade van swael korrosiebestande omhulsel en buise: 80SS, 95SS, 100SS, 110SS

Grade van hoë ineenstorting omhulsel en buise: 80HC, 95HC, 110HC, 125HC, 140HC

*Op tegniese ooreenkoms met kliënte om aan verskillende vraag na materiaal te voldoen

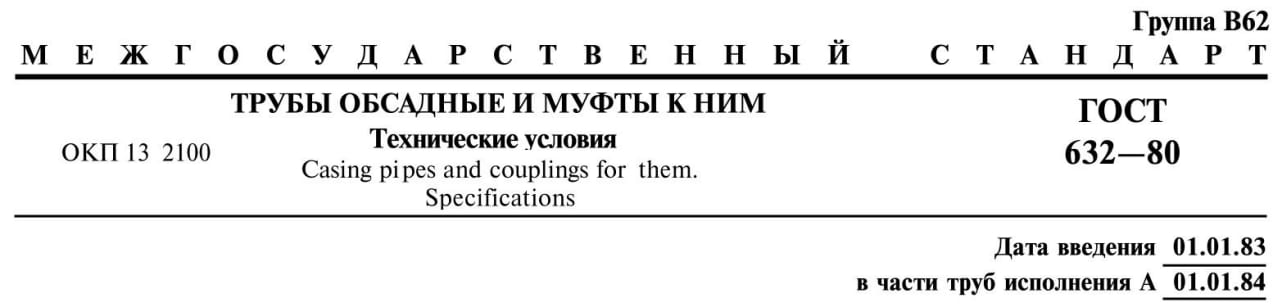

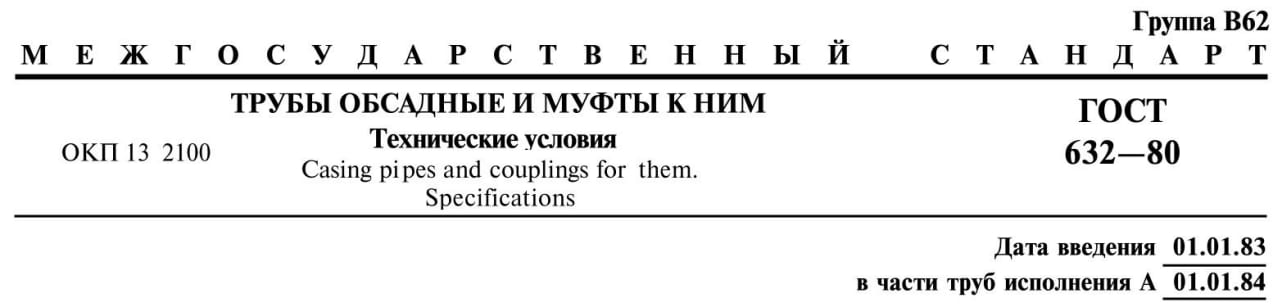

Gost -omhulsel en buise

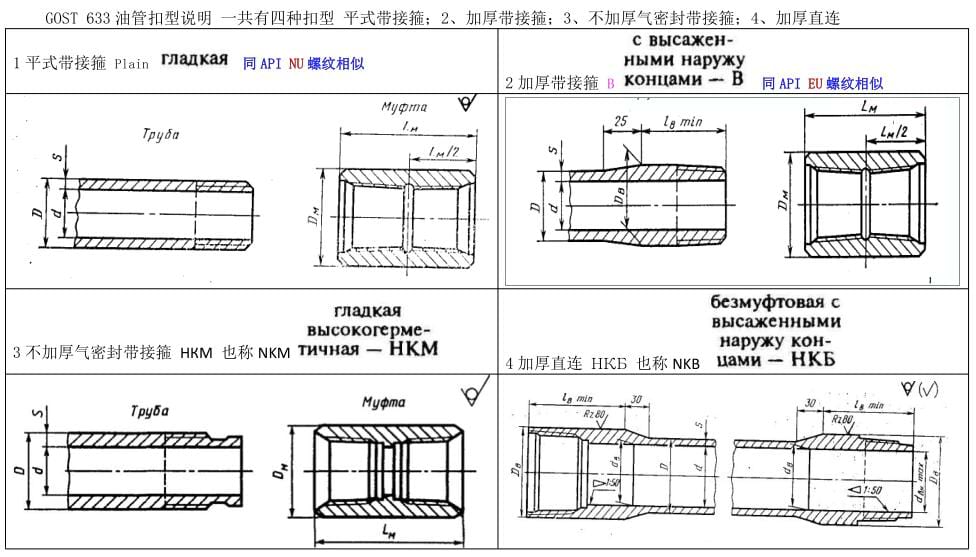

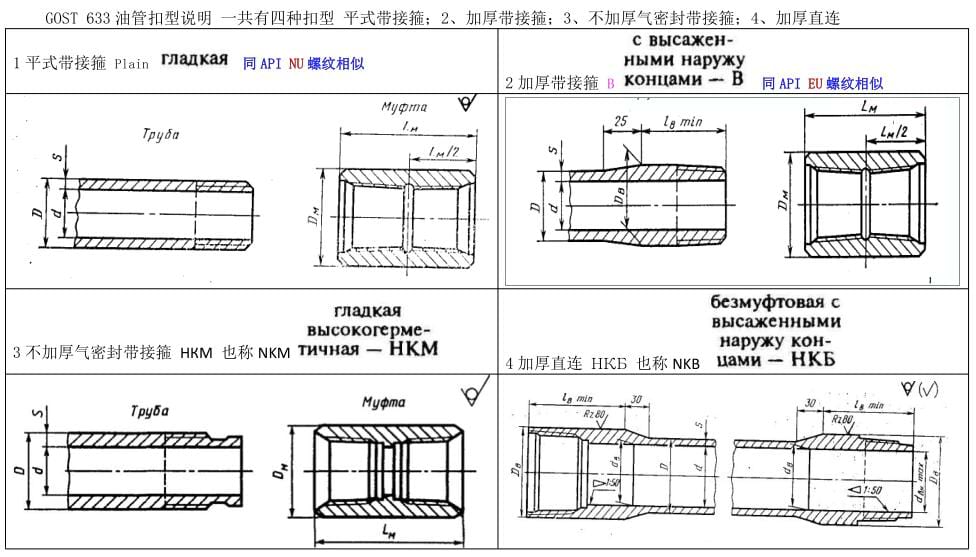

GOST Standard (GOST 632, GOST 633, GOST 8645) is standaard van omhulsel en buise wat hoofsaaklik deur Midde -Asiatiese lande gebruik word.

Verbinding:

Omhulsel: Ottm & Ottg

Buise: nu & eu