HDpe interiorem iactaret Tubing typically refers to Tubing ubi interiorem superficiem coated cum iacuit de summus density polyethylene (HDPE).

Applications of HDPE / Prope Tubing:

HDpe interiorem iactaret Tubing invenit Applications in Industries ubi corrosio resistentia, eget resistentia et diuturnitatem sunt. Commune Applications includit:

Oleum productio Wells: idoneam ad oleum puteos cum gravi eccentrici gerunt et corrosio olei fistularum, princeps potator virga defectum rate et scaling;

Currosive Gas Wells repugnans H2s et CO2 Gas corrosio;

Aqua iniectio bene apta aqua iniectio puteos gravi corrosio scaling;

Vetus Pipe Restituo: Redigendum oleum productio costs dum augendae ministerium vitae;

Transmissus Pipe: Vetus oleo fistulae cum gravibus corrosio et eccentrici lapsum quod non idoneam sub usu potest esse ut oleum partus fistulae post ursum.

Vestibulum processus:

In vestibulum processus involvat applicando iacuit HDPE ad interiorem superficiem Tubing. Hoc coating potest applicari per variis modi, ut extrusionem coating vel oblinit.

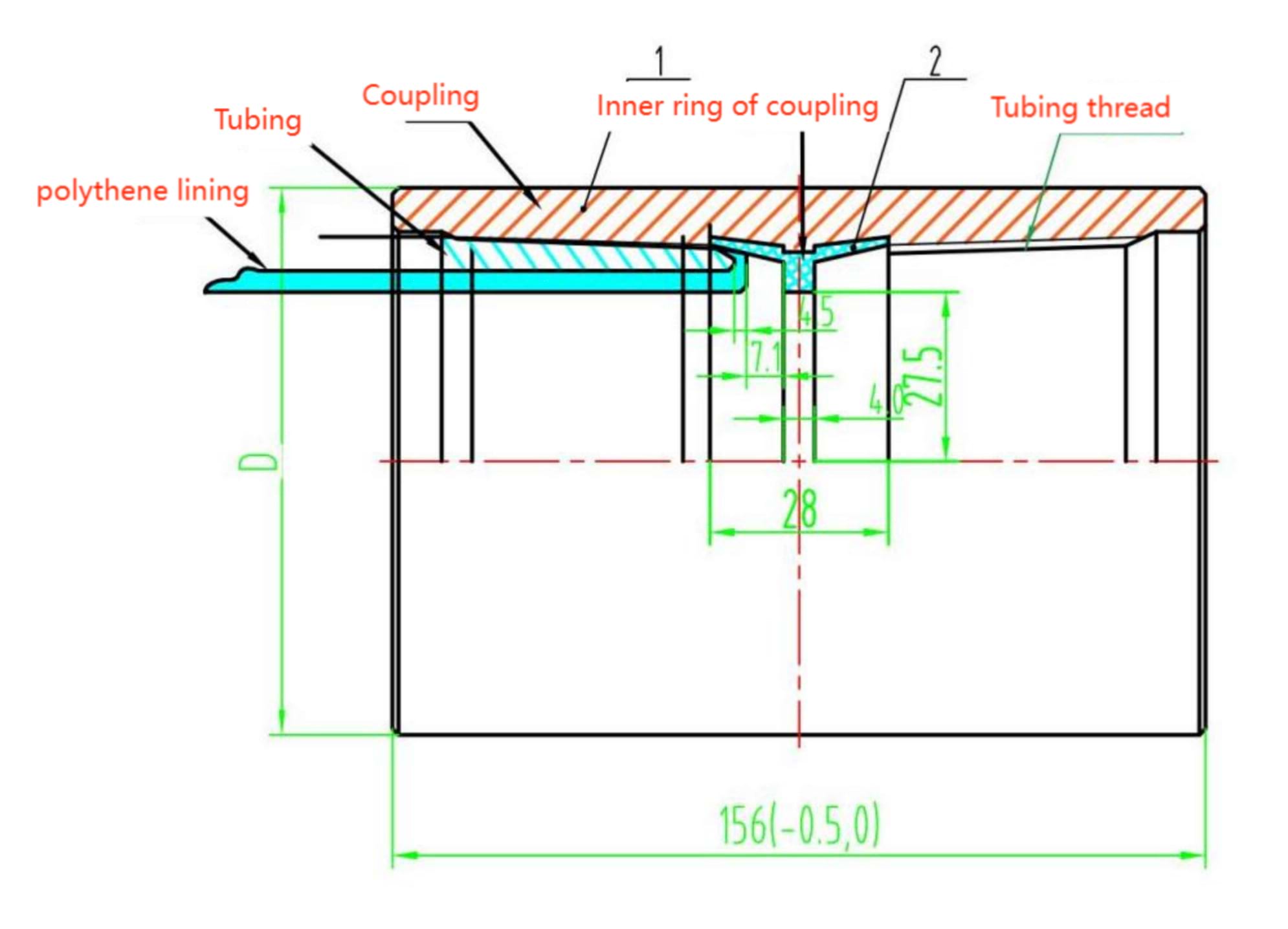

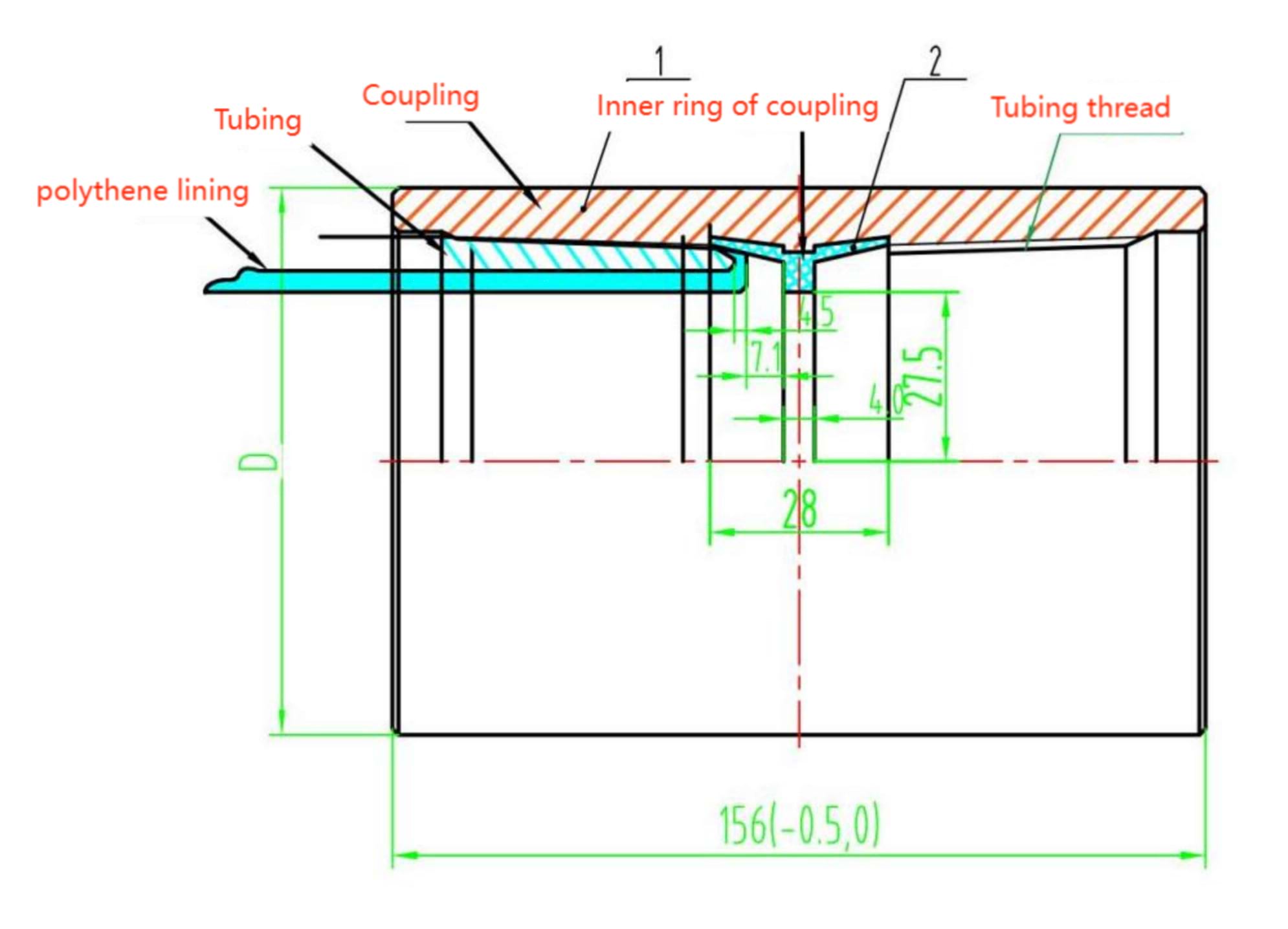

Through the special process of cold rolling and diameter reduction, it is pulled and penetrated into the inner cavity of ordinary oil pipes, and then placed naturally or boiled at 70°C to expand the liner, thereby completely filling the annular gap between the oil pipe and the liner to form an interference connection.

HDPE Tubing / HDPE liner potest complevit cum LABIUM in utroque fine.

Perficientur de oblinit materiae:

Auget M. pondus 0.94 ~ 0.97g / CM3

Vicat mollitur temperatus: ≧ CXXX ℃

Urget impulsum robore simpliciter sustentabat trabes: ≧ 50KJ / M2

Terensile Father Fortitudo: ≧ 20MPA

Litus obdurare: ≧ 65HD

Tensile elongatio ad confractus: ≧ CD%

Commoda:

ROSIO resistentia.

Chemical resistentia.

Reducitur frictio ad meliorem fluidum fluxus.

Aucta diuturnitatem.

Drawing of HDPE / ope lining Tubing