Tulerunt linea pipe refers to pipelines in transportandam fluidorum (ut oleum et Gas), quae sunt iactaret cum tutela materiae. Et coating applicantur ad exteriorem seu interior tibia ad augendae eius diuturnitatem, resistentia ad corrosionem et altiore perficientur.

Pipes potest applicari cum coatings includit octg (Casting et Tubing), seamless linea pipe, erw pipe, lsaw pipe, SSAW pipe caerimonias diversis industries.

Main genera coating in fistulae

Fusion-Bonded epoxy (FBE): Hoc est vulgaris coating pro linea tibia. FBE praebet optimum rorum resistentia et applicatur per calefacit tibia et applicando siccis pulveris quod liquescit et formae tutela iacuit super refrigerationem.

Three-Layer Polyethylene (3LPE) Or Polypropylene (3LPP): This coating system consists of three layers—an inner layer of fusion-bonded epoxy, a middle layer of adhesive, and an outer layer of polyethylene (3LPE) or polypropylene (3LPP). Hoc offert bonum corrosio praesidium et mechanica resistentia ad ferro pipes applicantur.

Concretum pondus coating (CWC): in quibusdam applications, tibiae, ut iactaret cum iacuit de concreto addere pondus et stabilitatem ad Pipeline in seabed. Hoc commune in Offshore Pipeline installations.

Signa et signa coating

Coating internum |

Type coating |

CONDUCTIO |

Liquid epoxy coating |

Awwa C210-2007 |

Fte |

Awwa c 213-2001 |

Cemento cæmento lining |

BS 534-1990, Awwa C205-2001 |

Bitumen coating |

BS 534-1990 |

Externum coating |

Type coating |

CONDUCTIO |

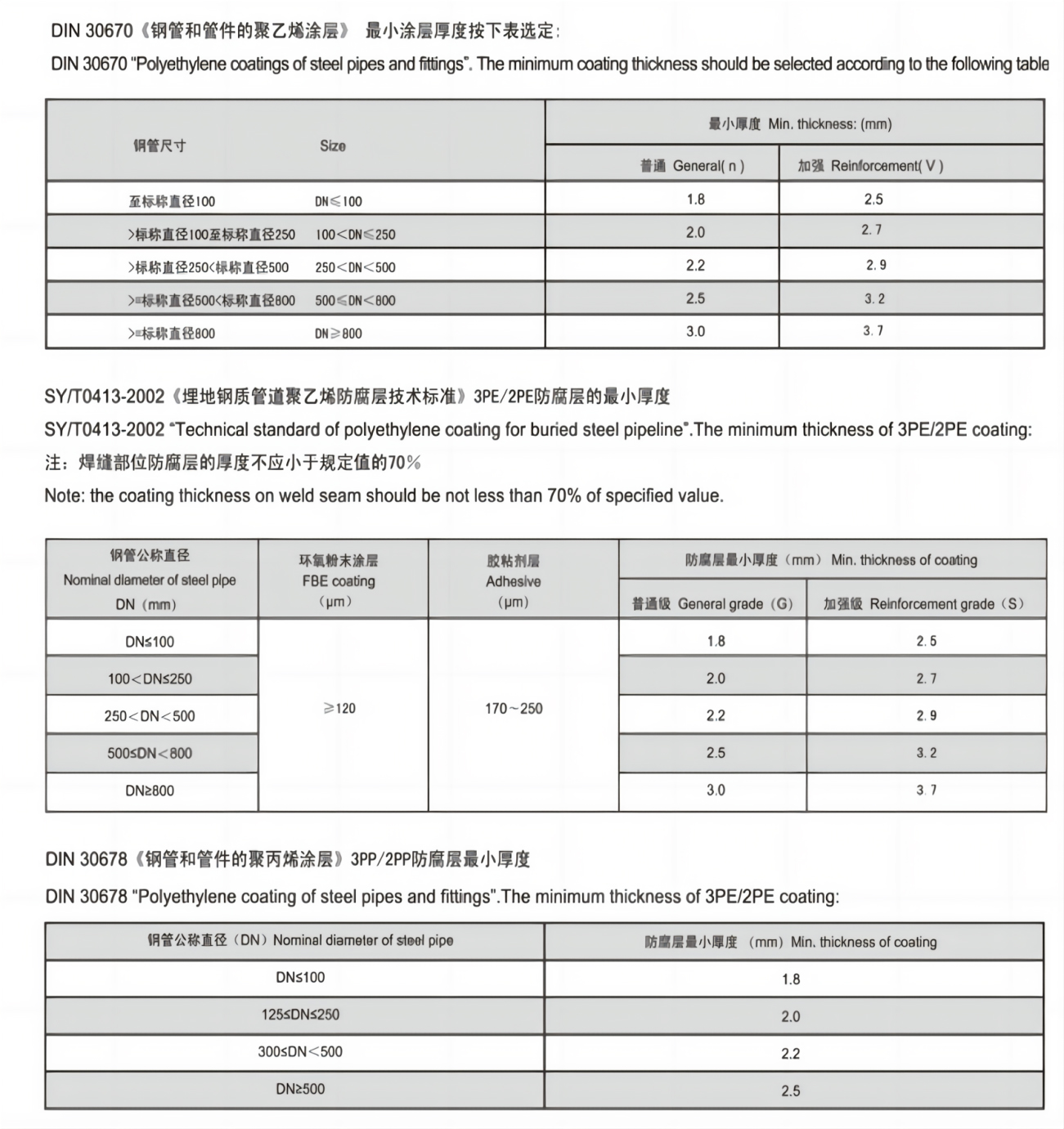

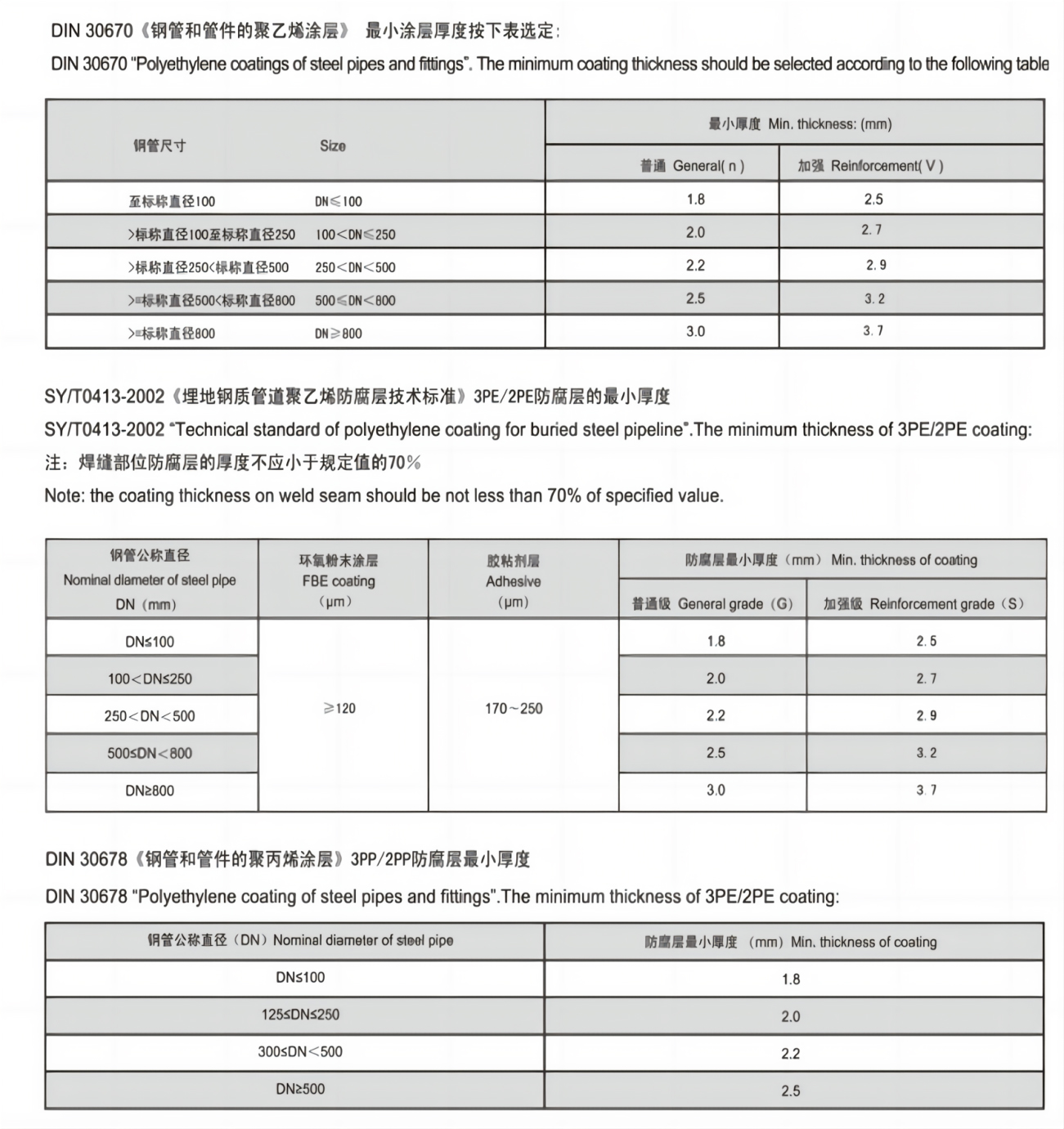

3Lpe / 3lpp coating |

Din 30670-1991, can / CSA Z245.21-2010,

ISO 21809-1-2009 SY / T 0413-2002 |

2Lpe / 2lpp coating |

Sy / T 0413-2002, ISO 21809-1-2009 |

(Fusion-vinculum epoxy) FBE |

Sy / T 0315-2005, AWWA c 213-2001, can / CSA Z245.20-2010,

ISO 21809-2-2007, API RP 5L9-2001 |

Bitumen coating / enamel & tape

calidum, applicari |

534-1990 BS, Awwwa203-2002, AWWA 214-2000 |

Liquid epoxy coating |

Awwa C210-2007 |

Polyurethane insulated coating |

Sy / T 0415-1996, CJ / T 114-2002, en 253-1994 |

Quality Index externum coating ferro Pipes